You can create clean energy at home by building your own fuel cell. This device converts chemical energy into electricity efficiently and with low environmental impact. You'll need core components like a proton exchange membrane, electrodes, and a bipolar plate, along with safety equipment and tools. Choose your fuel wisely, considering options like hydrogen or methanol. Assemble the cell carefully, connecting it to an inverter for power conversion. Regular maintenance and troubleshooting will keep your system running smoothly. While initial costs can be significant, long-term energy savings and environmental benefits make it worthwhile. Dive deeper to reveal the full potential of this innovative technology.

Understanding Fuel Cell Technology

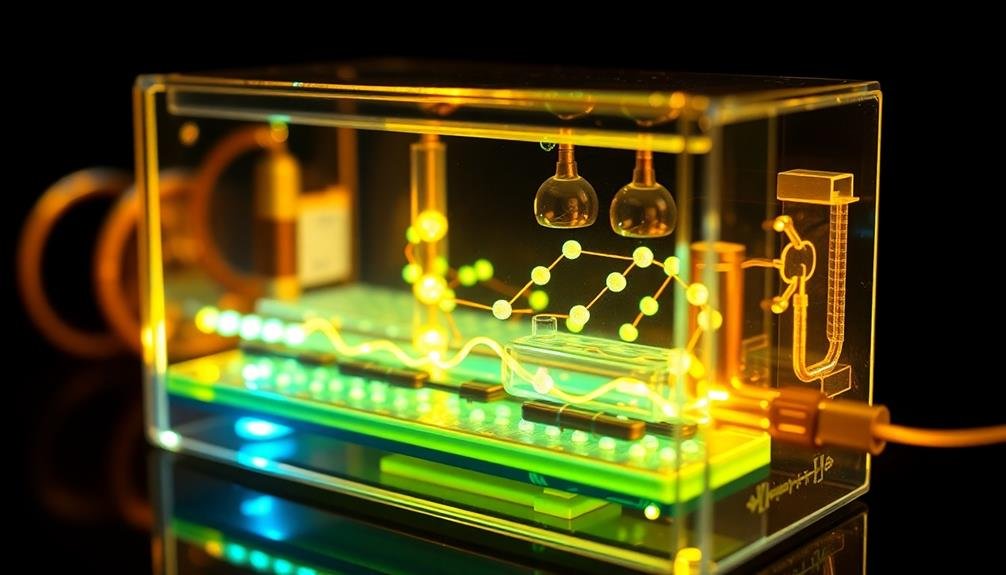

Grasping the basics of fuel cell technology is essential before diving into DIY projects. Fuel cells are electrochemical devices that convert chemical energy from fuel into electrical energy through a reaction with oxygen. Unlike batteries, fuel cells continuously produce electricity as long as fuel is supplied.

The core components of a fuel cell include an anode, cathode, and electrolyte. Hydrogen is typically used as fuel, entering the anode where it's split into protons and electrons. The protons pass through the electrolyte to the cathode, while electrons flow through an external circuit, generating electricity. At the cathode, oxygen combines with the protons and electrons, producing water as a byproduct.

There are various types of fuel cells, including Proton Exchange Membrane (PEM), Solid Oxide, and Alkaline. Each type has unique characteristics, operating temperatures, and applications. PEM fuel cells are often used in portable and automotive applications due to their low operating temperature and quick start-up time.

Efficiency is a key advantage of fuel cells, as they can convert up to 60% of fuel's energy into electricity, compared to internal combustion engines' 20-35% efficiency.

Required Materials and Tools

Preparation is key when starting on a DIY fuel cell project. You'll need to gather specific materials and tools before diving in. First, acquire the core components: a proton exchange membrane (PEM), catalyst-coated electrodes, and a bipolar plate. These form the heart of your fuel cell.

Don't forget hydrogen and oxygen sources, typically stored in pressurized tanks.

For assembly, you'll need:

- A soldering iron with lead-free solder

- Wire cutters and strippers

- A multimeter for testing connections

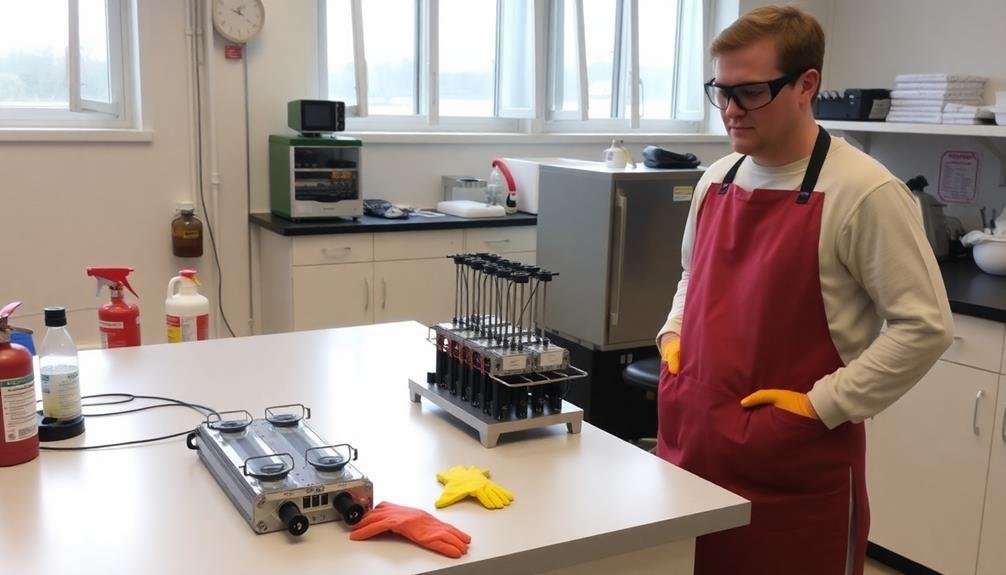

Secure safety equipment, including protective goggles, gloves, and a well-ventilated workspace.

You'll also need sealants, gaskets, and connectors to guarantee your fuel cell is airtight and properly connected.

Tools for measuring gas flow and pressure are essential. Consider investing in a flow meter and pressure gauge.

For testing, you'll want a variable resistor and an ammeter to measure current output.

Safety Precautions and Considerations

Safety is paramount when working with DIY fuel cells. You'll be dealing with potentially dangerous materials and processes, so it's essential to take proper precautions.

Always work in a well-ventilated area to prevent the buildup of hydrogen gas, which is highly flammable. Wear safety goggles, gloves, and a lab coat to protect yourself from chemical splashes and burns.

Keep a fire extinguisher nearby and never work alone. Avoid open flames or sparks in your work area.

When handling electrolytes, be extra cautious as they're corrosive and can cause severe burns. Always add acid to water, never the reverse, to prevent dangerous splashing.

Store your materials properly, keeping chemicals in clearly labeled, sealed containers.

Be aware of the risks associated with electrical components. Verify all connections are secure and insulated to prevent short circuits.

Don't operate your fuel cell in wet conditions or near water sources. Regularly inspect your setup for leaks or damage.

If you smell gas or notice any abnormalities, shut down the system immediately and evacuate the area.

Choosing the Right Fuel

For DIY fuel cells, selecting the appropriate fuel is essential to your project's success and safety.

You'll need to take into account factors like availability, cost, and efficiency when choosing your fuel source. The most common options for home fuel cells are hydrogen, methanol, and natural gas.

Hydrogen is the cleanest fuel, producing only water as a byproduct. It's highly efficient but can be challenging to store and handle safely.

Methanol is easier to store and transport, making it a popular choice for small-scale projects.

Natural gas is readily available in many homes, making it convenient for stationary fuel cells.

When deciding on your fuel, visualize:

- A hydrogen storage tank with proper safety valves and pressure regulators

- A methanol container with a secure cap and clear labeling

- A natural gas line connection with a properly installed shut-off valve

Take into account your local regulations and safety requirements when selecting your fuel.

You'll also need to verify you have the appropriate equipment for handling and storing your chosen fuel safely.

Assembling the Fuel Cell

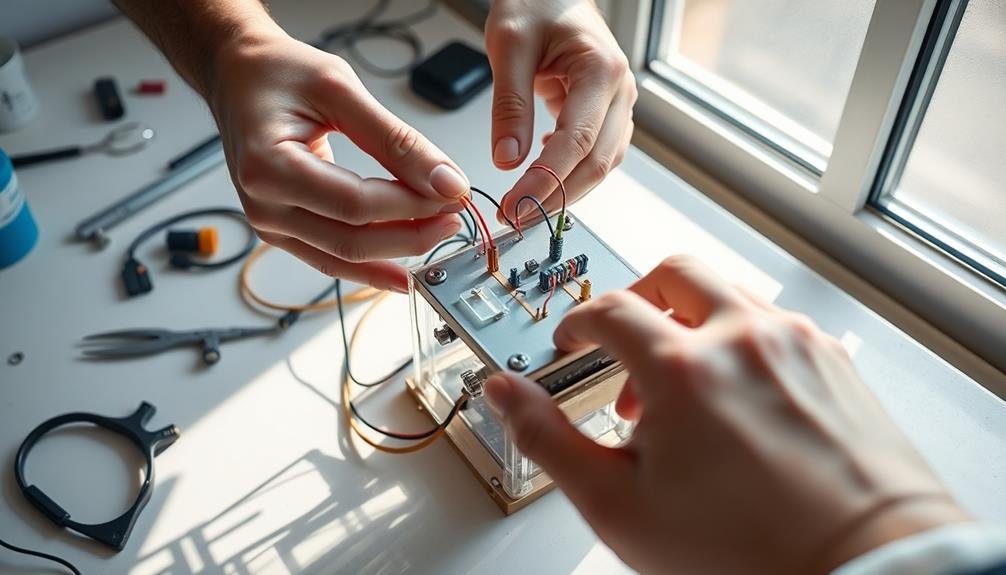

Assembling your DIY fuel cell involves three main components: the anode, cathode, and electrolyte. You'll need to carefully construct each part to guarantee peak performance.

Start by preparing the anode, typically made of a porous material like carbon paper coated with a catalyst such as platinum. Next, create the cathode using a similar process, but with a different catalyst suited for oxygen reduction.

For the electrolyte, you'll use a proton exchange membrane (PEM) sandwiched between the anode and cathode. This membrane allows protons to pass through while blocking electrons. Carefully align these components and secure them with gaskets to prevent leaks.

Now, it's time to add the bipolar plates. These plates collect current and distribute fuel and air across the cell. Attach them to either side of your assembled membrane electrode assembly (MEA). Make sure to include flow channels for efficient gas distribution.

Connecting to Home Power Systems

Once you've assembled your DIY fuel cell, integrating it into your home power system is the next essential step. You'll need to connect your fuel cell to an inverter, which converts the DC power produced by the fuel cell into AC power compatible with your home's electrical system. Choose an inverter that matches your fuel cell's output capacity and your home's power requirements.

Before making any connections, verify your main power supply is turned off to prevent electrical accidents. Connect the fuel cell's positive and negative terminals to the inverter's corresponding inputs. Then, link the inverter's output to your home's electrical panel through a dedicated circuit breaker.

To create a seamless integration with your existing power system:

- Install a transfer switch to automatically switch between grid power and your fuel cell.

- Add a battery bank to store excess energy for use during peak demand periods.

- Implement a smart energy management system to optimize power distribution.

Remember to comply with local building codes and regulations. It's advisable to consult a licensed electrician to verify proper installation and safety.

With your fuel cell connected, you'll be able to generate clean, efficient power for your home.

Maintenance and Troubleshooting

Regular maintenance is essential to keep your DIY fuel cell running efficiently and extend its lifespan. You'll need to check the system monthly, inspecting all connections, hoses, and seals for signs of wear or damage. Replace any worn parts immediately to prevent leaks or performance issues.

Monitor your fuel cell's performance regularly by tracking its voltage output and efficiency. If you notice a decline, it's time to clean the electrodes. Use distilled water and a soft brush to remove any buildup, being careful not to damage the delicate components. You should also flush the system annually with a manufacturer-approved cleaning solution.

If you encounter problems, start by checking the basics: guarantee proper fuel supply, verify all electrical connections, and confirm that the cooling system is functioning correctly.

Common issues include low power output, which could indicate a clogged fuel filter or degraded catalyst, and unexpected shutdowns, often caused by overheating or fuel starvation. For more complex problems, consult your fuel cell's manual or seek advice from a professional.

Optimizing Fuel Cell Efficiency

With your fuel cell up and running, you'll want to maximize its performance. Start by monitoring the cell's voltage and current output regularly. This will help you identify any drops in efficiency early on.

Keep the fuel cell's operating temperature within the best range specified by the manufacturer, as temperature fluctuations can greatly impact performance.

Guarantee a consistent and pure fuel supply. Contaminants in the hydrogen or oxygen can decrease efficiency and damage the cell over time. Regularly check and clean the gas flow channels to prevent blockages.

Maintain proper humidity levels within the cell to enhance the membrane's conductivity.

To visualize the enhancement process, consider these key steps:

- Adjust the fuel flow rate to match the electrical load demand

- Fine-tune the air pressure to guarantee best reactant distribution

- Implement a heat management system to maintain ideal operating temperatures

Remember to periodically calibrate your monitoring instruments for accurate readings.

Scaling Up Your System

To scale up your DIY fuel cell system, you'll want to focus on three key areas.

You can increase power output by optimizing individual cell performance and enhancing catalyst efficiency.

Adding multiple cells in series or parallel configurations will boost overall system capacity.

Increasing Power Output

Scaling up your fuel cell system can greatly boost its power output. To increase the power, you'll need to connect multiple fuel cells in series or parallel configurations. Series connections increase voltage, while parallel connections increase current.

When designing your expanded system, consider factors like fuel supply, cooling requirements, and electrical load management.

To optimize your fuel cell stack's performance:

- Guarantee uniform fuel distribution across all cells

- Implement efficient heat management systems

- Monitor and maintain proper humidity levels

You can also enhance power output by improving electrode materials and catalysts. Consider using advanced materials like platinum-based catalysts or carbon nanotubes to increase reaction rates and efficiency.

Additionally, optimize the flow field design to improve reactant distribution and water management within the cell.

Don't forget to upgrade your auxiliary systems as you scale up. This includes fuel storage, power conditioning equipment, and safety systems. Proper sizing of these components is vital for maintaining system stability and efficiency.

Adding Multiple Cells

After mastering a single fuel cell, you're ready to scale up your system by adding multiple cells. This process involves connecting individual cells in series or parallel configurations to increase voltage or current output, respectively. When adding cells, confirm proper insulation and secure connections to maintain efficiency and safety.

Consider these factors when scaling up your fuel cell system:

| Factor | Series Connection | Parallel Connection |

|---|---|---|

| Voltage | Increases | Remains constant |

| Current | Remains constant | Increases |

| Resistance | Increases | Decreases |

To add cells in series, connect the positive terminal of one cell to the negative terminal of the next. This configuration boosts voltage output, ideal for powering higher-voltage devices. For parallel connections, link all positive terminals together and all negative terminals together. This setup increases current output, suitable for applications requiring higher amperage.

When scaling up, monitor temperature and pressure across all cells to confirm consistent performance. Use a charge controller to regulate output and prevent overcharging. Remember to adjust your fuel supply system to accommodate the increased demand from multiple cells. With careful planning and execution, you'll create a more powerful and versatile fuel cell system for your clean energy needs.

Expanding Storage Capacity

Your fuel cell system's storage capacity plays an essential role in its overall performance and utility. To expand your system's storage, you'll need to add more hydrogen tanks or increase the size of your existing ones. This allows you to store excess energy produced during peak hours for use during periods of high demand or low production.

When expanding your storage capacity, consider these factors:

- Space requirements: Larger tanks take up more room, so make certain you have adequate space for expansion.

- Safety considerations: Proper ventilation and leak detection systems become even more critical as you increase hydrogen storage.

- Pressure management: Higher storage capacity often means higher pressures, requiring robust pressure regulation equipment.

To scale up your system effectively, start by calculating your daily energy needs and determining how much additional storage you require.

Then, choose appropriately sized tanks and install them in parallel with your existing setup. Don't forget to upgrade your pressure regulators and safety systems accordingly.

As you expand, regularly inspect all connections and components to maintain system integrity.

With increased storage capacity, you'll be able to maximize your fuel cell's efficiency and rely less on the grid, bringing you closer to energy independence.

Cost Analysis and Savings

You'll need to evaluate the initial investment when building your DIY fuel cell system.

Break down costs for components like electrodes, membranes, catalysts, and auxiliary equipment to understand your upfront expenses.

Over time, you can calculate your long-term energy savings by comparing your fuel cell's efficiency and operating costs to traditional energy sources.

Initial Investment Breakdown

Building a DIY fuel cell often requires a significant upfront investment, but the long-term savings can be substantial. When breaking down the initial costs, you'll need to take into account several key components.

The fuel cell stack itself is typically the most expensive item, ranging from $500 to $3,000 depending on power output. You'll also need a hydrogen storage system, which can cost between $200 and $1,000. Don't forget about the power inverter, essential for converting DC to AC power, which may set you back $300 to $800.

Other necessary items include:

- Pressure regulators and valves ($100-$300)

- Wiring and connectors ($50-$150)

- Safety equipment like hydrogen sensors ($200-$500)

You'll also need to factor in the cost of tools if you don't already have them.

While these expenses can add up quickly, remember that you're investing in a long-term, clean energy solution. By carefully sourcing components and potentially repurposing some materials, you can reduce your initial outlay.

As you plan your budget, take into account the potential energy savings and environmental benefits that'll offset your investment over time.

Long-Term Energy Savings

While the initial investment in a DIY fuel cell may seem steep, the long-term energy savings can be substantial. You'll start seeing returns on your investment within the first few years of operation.

On average, homeowners can expect to reduce their electricity bills by 40-60% annually, depending on local energy costs and consumption patterns.

To calculate your potential savings, compare your current monthly energy bills to the estimated output of your fuel cell system. Factor in the cost of hydrogen fuel, which is typically cheaper than grid electricity.

Don't forget to take into account maintenance costs, which are generally low for fuel cells due to their lack of moving parts.

Over a 10-year period, you could save anywhere from $15,000 to $30,000 on energy costs. This estimate accounts for the initial investment and ongoing fuel expenses.

Additionally, you may qualify for tax incentives or rebates, further offsetting your costs. Some homeowners even sell excess energy back to the grid, creating an additional income stream.

As fuel cell technology advances, efficiency will improve, potentially increasing your savings over time.

Environmental Impact Assessment

An environmental impact assessment is essential when evaluating DIY fuel cell projects. You'll need to assess how your fuel cell system affects the environment compared to traditional energy sources.

While fuel cells generally have a lower carbon footprint, it's vital to take into account the entire lifecycle of your project.

Start by examining the materials used in your fuel cell. Some components may require rare earth elements or precious metals, which can have significant environmental impacts during extraction and processing.

Next, assess the fuel source you'll use. Hydrogen is the most common fuel for residential fuel cells, but its production method greatly influences its environmental impact.

Reflect on these key factors in your assessment:

- Emissions reduction potential compared to your current energy source

- Water consumption and waste production of your fuel cell system

- End-of-life disposal or recycling options for fuel cell components

Legal and Regulatory Considerations

When building a DIY fuel cell, you'll need to navigate various legal and regulatory hurdles.

Check your local zoning laws and obtain necessary permits before starting your project.

You must also guarantee your fuel cell setup complies with all applicable safety codes, including electrical and fire safety regulations.

Zoning and Permit Requirements

Before diving into your DIY fuel cell project, you'll need to navigate three key legal and regulatory hurdles. First, check your local zoning laws to verify fuel cells are permitted in your area. Some municipalities have strict regulations on alternative energy systems, especially in residential zones.

Next, contact your city's building department to inquire about permit requirements. You'll likely need to submit detailed plans and specifications for your fuel cell setup.

When applying for permits, be prepared to provide:

- A site plan showing the proposed location of your fuel cell

- Electrical diagrams outlining how the system will connect to your home's power grid

- Safety protocols and emergency shutdown procedures

Don't forget to consult with your homeowners' association if you live in a planned community. They may have additional restrictions or approval processes.

Remember, obtaining proper permits isn't just about compliance; it's vital for guaranteeing your fuel cell system is safe and properly integrated into your home's infrastructure.

Failure to secure necessary permits could result in fines, forced removal of your system, or complications with your home insurance. Stay informed and follow all local regulations to enjoy the benefits of your DIY fuel cell project worry-free.

Safety Codes Compliance

In addition to zoning and permit requirements, you'll need to assure your DIY fuel cell project complies with all relevant safety codes. These codes guarantee your installation is safe for you, your family, and your community. Start by researching national, state, and local safety regulations specific to fuel cells and hydrogen systems.

Key areas of compliance include electrical safety, fire prevention, ventilation, and hazardous materials handling. You'll need to adhere to standards set by organizations like the National Fire Protection Association (NFPA) and the International Code Council (ICC).

Here's a quick reference guide for common safety codes:

| Code | Description | Relevance |

|---|---|---|

| NFPA 853 | Installation of Stationary Fuel Cell Power Systems | Overall system safety |

| NFPA 70 | National Electrical Code | Electrical connections |

| ICC IFGC | International Fuel Gas Code | Fuel handling and storage |

| NFPA 55 | Compressed Gases and Cryogenic Fluids Code | Hydrogen storage |

| OSHA 1910 | Occupational Safety and Health Standards | Workplace safety |

Future of Home Fuel Cells

The future of home fuel cells looks bright, with innovations coming down the pipeline. You'll likely see more efficient and affordable fuel cell systems hitting the market in the coming years. These advancements will make it easier for homeowners to generate their own clean energy and reduce their reliance on the grid.

As technology progresses, you can expect to see:

- Smaller, more compact fuel cell units that'll fit seamlessly into your home's existing infrastructure

- Enhanced durability and longer lifespans, reducing the need for frequent maintenance or replacements

- Integration with smart home systems for ideal energy management and cost savings

You'll also witness improvements in fuel cell efficiency and power output, allowing you to power more of your home's appliances and electronics. Manufacturers are working on developing fuel cells that can run on a variety of fuels, giving you more flexibility in your energy choices.

As costs continue to decrease, home fuel cells will become increasingly accessible to a wider range of consumers. This shift will contribute to a cleaner, more sustainable energy landscape for residential areas, potentially revolutionizing how we power our homes in the future.

Frequently Asked Questions

Can Fuel Cells Be Used in Apartments or Rental Properties?

You can use fuel cells in apartments or rental properties. They're compact and don't require major modifications. However, check with your landlord or property manager first, as there may be restrictions or safety concerns to address.

How Noisy Are Home Fuel Cell Systems During Operation?

You'll be pleased to know that home fuel cell systems are generally quiet during operation. They produce a low hum, similar to a refrigerator. You won't find them disruptive, even in close living spaces.

Are There Any Odors Associated With Running a Home Fuel Cell?

You'll typically experience no odors from running a home fuel cell. They're designed to operate cleanly and efficiently. However, if you smell anything unusual, it's important to shut down the system and contact a professional immediately.

Can Fuel Cells Power High-Energy Appliances Like Air Conditioners or Electric Stoves?

Yes, you can power high-energy appliances with fuel cells. They're capable of generating enough electricity for air conditioners and electric stoves. However, you'll need a larger or multiple fuel cells to meet the increased energy demands of these appliances.

How Do Extreme Weather Conditions Affect Fuel Cell Performance?

You'll find that extreme weather impacts fuel cell performance. In cold conditions, they're less efficient and may struggle to start. Hot weather can cause overheating issues. High humidity affects water management, potentially reducing output and efficiency.

In Summary

You've now got the knowledge to build your own fuel cell at home. Remember to prioritize safety, follow regulations, and choose your fuel wisely. While it's an exciting DIY project, consider the costs and environmental impact. As technology advances, home fuel cells may become more accessible and efficient. Keep exploring clean energy options and stay informed about developments in this field. You're contributing to a greener future!

Leave a Reply