To fix common home fuel cell system problems, start by regularly monitoring stack performance and electrical connections. Check for water management issues and guarantee proper hydrogen supply. Keep air flow unobstructed by cleaning filters and vents. Address catalyst contamination promptly and maintain balance of plant components. Don't neglect safety systems; test gas sensors and emergency shut-offs regularly. Optimize your maintenance schedule based on manufacturer recommendations and usage patterns. Create monthly, quarterly, and annual checklists for thorough inspections and repairs. By staying proactive, you'll maximize your fuel cell's efficiency and lifespan. Dive deeper to master the intricacies of fuel cell maintenance.

Fuel Cell Stack Performance Issues

Fuel cell stack performance issues can greatly impact your home's energy efficiency. These problems often manifest as reduced power output, increased fuel consumption, or premature system shutdowns. To diagnose stack issues, monitor your system's voltage and current output regularly. A significant drop in these values may indicate degradation of the stack's components.

Common causes of stack performance decline include membrane dehydration, catalyst poisoning, and uneven reactant distribution. You'll need to check your system's humidification levels and guarantee proper water management to prevent membrane issues.

Catalyst poisoning often results from contaminants in the fuel supply, so it's vital to use high-quality, clean fuel sources. To address uneven reactant distribution, inspect and clean your system's flow channels periodically. This helps maintain ideal gas flow across the stack.

If you notice a sudden performance drop, it could be due to a leak in the stack. Perform a leak test using soap solution to identify and seal any breaches.

Regular maintenance, including cleaning and replacing filters, can prevent many stack issues. If problems persist, consult a professional technician specializing in fuel cell systems for more advanced diagnostics and repairs.

Electrical Connection Troubleshooting

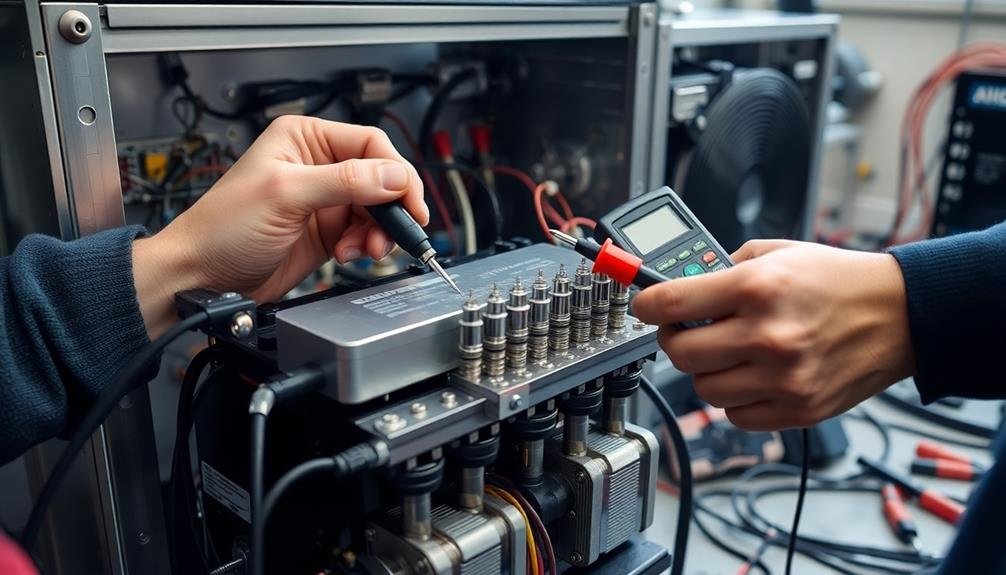

When troubleshooting electrical connections in your home fuel cell system, start by carefully inspecting all wires for any signs of looseness or damage.

You'll want to check each connection point, ensuring that wires are securely fastened and free from corrosion or wear.

To further diagnose potential issues, use a multimeter to measure voltage at key points in the system, comparing the readings to the manufacturer's specifications.

Loose Wire Inspection

Inspecting for loose wires is an essential step in troubleshooting electrical connections in your home fuel cell system. Loose connections can cause intermittent power issues, reduced efficiency, and even system shutdowns.

You'll need to carefully examine all wiring connections, from the fuel cell stack to the inverter and power distribution panel.

To perform a thorough loose wire inspection:

- Turn off your fuel cell system and disconnect the main power source.

- Open access panels to expose wiring connections.

- Visually inspect all terminals, connectors, and junction boxes for signs of corrosion or damage.

- Gently wiggle each wire to check for looseness.

Use a multimeter to test continuity between connection points if you suspect a break in the wiring. Pay special attention to areas prone to vibration or temperature fluctuations, as these conditions can cause connections to loosen over time.

Don't forget to check grounding wires, as they're vital for system safety and performance.

If you find any loose connections, tighten them carefully using the appropriate tools. For damaged wires or connectors, replacement may be necessary.

Always consult your system's manual or a professional technician if you're unsure about any aspect of the inspection or repair process.

Voltage Measurement Techniques

Accurate voltage measurements are essential for diagnosing electrical issues in your home fuel cell system. To take these measurements, you'll need a digital multimeter with probes. Always verify the meter is set to the correct voltage range before testing.

Begin by checking the main output voltage at the fuel cell stack terminals. Compare this reading to the manufacturer's specifications. If it's low, you may have a faulty cell or connection issue.

Next, measure the voltage across individual cells to identify any that aren't performing at their best. Don't forget to test auxiliary components like pumps and fans. Measure their input voltages to confirm they're receiving the correct power. If you find discrepancies, trace the wiring back to the source.

When measuring DC voltages, pay attention to polarity. Reverse the probes if you get a negative reading. For AC voltages, polarity doesn't matter, but be sure to use the appropriate AC setting on your meter.

Remember to check ground connections too. A poor ground can cause erratic system behavior. Measure the voltage between various ground points and the main system ground to identify potential issues.

Water Management System Failures

Water management system failures frequently plague home fuel cell systems, causing significant performance issues and potential damage.

You'll need to address these problems promptly to maintain peak performance and extend your system's lifespan. Common signs of water management issues include reduced power output, unstable voltage, and unusual noises from the fuel cell stack.

To troubleshoot and fix water management system failures:

- Check for clogged water channels: Inspect and clean the water flow paths to guarantee proper circulation.

- Examine the humidifier: Verify it's functioning correctly to maintain the right moisture levels in the fuel cell stack.

- Verify pump operation: Test the water pump for proper functionality and replace if necessary.

- Monitor condensation: Address any excess water accumulation in the system to prevent flooding.

You should also regularly inspect seals and gaskets for leaks, as these can disrupt water balance.

If you're uncomfortable performing these tasks, consult a professional technician. Preventive maintenance, including periodic system flushes and water quality checks, can help avoid future water management issues.

Hydrogen Supply Problems

With hydrogen as the lifeblood of fuel cell systems, supply problems can quickly bring your home's power generation to a halt. You'll need to address these issues promptly to maintain a steady energy supply. Common hydrogen supply problems include leaks, blockages, and pressure irregularities.

First, check for leaks in your hydrogen storage tanks, pipes, and connections. Use a hydrogen detector to identify any escaping gas. If you find a leak, shut off the main supply valve immediately and call a certified technician for repairs.

Don't attempt to fix hydrogen leaks yourself, as it's extremely dangerous.

Blockages can occur due to contaminants or component failures. Inspect your fuel lines and filters regularly, replacing them as needed. If you notice reduced power output, it might indicate a partial blockage.

Pressure problems can stem from faulty regulators or temperature fluctuations. Verify your hydrogen storage area maintains a consistent temperature and that regulators are functioning correctly.

If you're experiencing frequent pressure drops, consult a professional to diagnose and resolve the issue.

Lastly, monitor your hydrogen consumption and schedule refills well in advance to avoid running out of fuel unexpectedly.

Air Flow Obstructions

Air flow obstructions can greatly impact your home fuel cell's performance.

You'll need to understand common causes of blockages, recognize signs of restricted airflow, and learn effective methods for clearing obstructions.

Causes of Air Blockages

Proper airflow is essential for the efficient operation of home fuel cells. When air blockages occur, they can greatly reduce your system's performance and potentially lead to damage. Understanding the common causes of these blockages can help you prevent and address them quickly.

Several factors can contribute to air flow obstructions in your home fuel cell system:

- Dust and debris accumulation: Over time, dust, pollen, and other airborne particles can build up in the air intake vents and filters.

- Insect or small animal nests: These can form in or around the air intake areas, blocking the flow of air into the system.

- Damaged or bent venting components: Physical damage to the venting system can create pinch points that restrict airflow.

- Improperly installed or maintained filters: Clogged or incorrectly fitted filters can impede air movement through the system.

You'll need to regularly inspect your fuel cell's air intake and venting components to catch these issues early.

Clean or replace filters as recommended by the manufacturer, and verify that the area around your system is free from obstructions.

If you notice a decrease in your fuel cell's performance, check for air blockages as part of your troubleshooting process.

Detecting Flow Restrictions

Detecting air flow obstructions early is essential to maintaining your home fuel cell's efficiency. You'll need to be vigilant and perform regular checks to identify potential blockages before they become serious issues. Listen for unusual noises, such as whistling or gurgling, which can indicate restricted airflow. Monitor your system's performance metrics, paying close attention to power output and fuel consumption rates.

Use these methods to detect flow restrictions:

| Method | Description | Frequency | Tools Needed |

|---|---|---|---|

| Visual Inspection | Check filters and vents for debris | Weekly | Flashlight |

| Pressure Test | Measure air pressure at key points | Monthly | Pressure gauge |

| Flow Rate Analysis | Compare actual vs. expected flow rates | Quarterly | Flow meter |

| Thermal Imaging | Identify hot spots indicating blockages | Annually | Thermal camera |

If you notice a sudden drop in performance or efficiency, it's vital to investigate immediately. Don't hesitate to call a professional if you're unsure about interpreting test results or handling complex diagnostics. Regular maintenance and prompt attention to potential flow restrictions will help guarantee your home fuel cell system operates at peak efficiency, saving you money and reducing the risk of unexpected shutdowns.

Clearing Airway Obstructions

Once you've detected an airflow obstruction in your home fuel cell system, what's the next step? You'll need to clear the obstruction to restore proper functioning. Start by turning off the system and allowing it to cool down completely.

Then, carefully inspect the air intake and exhaust vents for any visible blockages.

To effectively clear airway obstructions, follow these steps:

- Remove debris: Use a soft brush or vacuum cleaner to gently remove any dust, leaves, or other debris from the vents.

- Clean filters: If your system has air filters, remove and clean them according to the manufacturer's instructions.

- Check for internal blockages: If external cleaning doesn't solve the issue, you may need to inspect the internal air passages. Consult your user manual for guidance on accessing these areas safely.

- Address recurring issues: If obstructions are a frequent problem, consider installing protective screens or relocating your fuel cell system to a cleaner environment.

After clearing the obstruction, restart your system and monitor its performance. If problems persist, you may need to call a professional technician for a more thorough inspection and cleaning.

Regular maintenance can help prevent future airway obstructions and guarantee your home fuel cell system operates efficiently.

Temperature Control Malfunctions

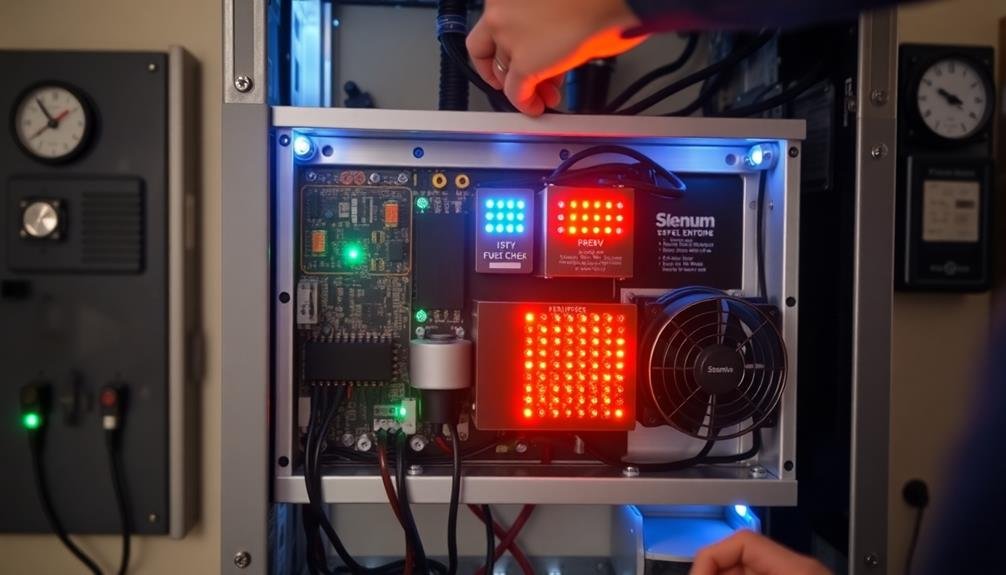

Within the domain of home fuel cell systems, temperature control malfunctions can be a significant headache for homeowners. These issues often stem from faulty sensors, clogged cooling systems, or malfunctioning control boards. If you notice your fuel cell system isn't maintaining the correct operating temperature, it's vital to address the problem promptly.

First, check the temperature sensors for accuracy. You can do this by comparing their readings with those of a reliable thermometer. If they're off, you'll need to recalibrate or replace them.

Next, inspect the cooling system for any blockages or leaks. Clean out any debris and confirm proper coolant levels. If the problem persists, the control board might be the culprit. Look for signs of electrical damage or loose connections.

Don't hesitate to call a professional if you're unsure about handling these repairs yourself. They can diagnose the issue more accurately and perform necessary repairs safely.

Regular maintenance can prevent many temperature control problems. Keep your system clean, check for wear and tear, and schedule annual inspections. By staying proactive, you'll guarantee your home fuel cell system operates efficiently and reliably for years to come.

Inverter and Power Output Concerns

When troubleshooting your home fuel cell system, you'll likely encounter inverter and power output issues.

You may notice power fluctuations and instability, which can stem from inverter efficiency problems or output capacity limitations.

It's essential to address these concerns promptly to guarantee your fuel cell operates at peak performance and delivers reliable power to your home.

Power Fluctuations and Instability

Consistency is key when it comes to your home fuel cell's power output. If you're experiencing power fluctuations or instability, it's essential to address these issues promptly to guarantee reliable energy supply and protect your connected devices.

Power fluctuations can stem from various factors, including fuel quality, system maintenance, and environmental conditions.

To troubleshoot and resolve power fluctuations:

- Check fuel quality: Confirm you're using clean, high-quality fuel that meets your system's specifications.

- Inspect fuel lines: Look for blockages or leaks that might be causing irregular fuel flow.

- Clean or replace filters: Clogged filters can lead to inconsistent fuel delivery and power output.

- Monitor temperature and humidity: Extreme conditions can affect your fuel cell's performance.

If these steps don't resolve the issue, examine your system's control board and sensors. Faulty components can cause erratic power output. You may need to recalibrate or replace these parts to restore stability.

Don't hesitate to consult a professional technician if you're unsure about any aspect of your fuel cell system. Regular maintenance and prompt attention to fluctuations will help guarantee your home fuel cell continues to provide reliable, efficient power for your household needs.

Inverter Efficiency Issues

Maximizing your home fuel cell's efficiency hinges on a properly functioning inverter. This vital component converts the DC power produced by your fuel cell into AC power for your home's electrical system. When your inverter isn't operating at peak efficiency, you'll notice decreased overall system performance and potentially higher energy costs.

To identify inverter efficiency issues, monitor your system's output closely. Look for unexplained drops in power production or inconsistencies between the fuel cell's generation and your home's usable electricity. You might also hear unusual noises or notice excessive heat coming from the inverter.

To address these problems, first verify your inverter is correctly sized for your fuel cell system. An undersized or oversized inverter can greatly impact efficiency.

Regularly clean the inverter's cooling fins and vents to prevent overheating. Check and tighten all electrical connections, as loose wires can cause power loss and safety hazards.

If you're experiencing persistent issues, consider upgrading to a more advanced inverter with features like maximum power point tracking (MPPT) or smart grid integration. These technologies can enhance your system's overall efficiency and adapt to varying power demands more effectively.

Output Capacity Limitations

Beyond inverter efficiency, your home fuel cell system's output capacity plays a key role in its overall performance.

Output capacity limitations can greatly impact your ability to power your home effectively. Understanding these limitations and how to address them is essential for maximizing your fuel cell system's potential.

To overcome output capacity limitations, consider the following steps:

- Assess your energy needs: Calculate your household's peak and average power consumption to determine if your current fuel cell system meets your requirements.

- Upgrade your fuel cell stack: If your system consistently falls short, consider installing a larger or more powerful fuel cell stack to increase output capacity.

- Implement load management: Use smart home technology to distribute power consumption evenly throughout the day, reducing strain on your fuel cell system during peak hours.

- Install energy storage: Add batteries to your setup to store excess energy during low-demand periods and supplement power during high-demand times.

Membrane Degradation and Replacement

Maintaining the health of your fuel cell's membrane is essential for peak performance. Over time, the membrane can degrade due to various factors, including chemical contamination, mechanical stress, and temperature fluctuations.

You'll notice reduced efficiency and power output as the membrane deteriorates. To prevent premature degradation, verify you're using high-quality fuel and following the manufacturer's maintenance guidelines.

Regularly check for signs of wear, such as thinning or discoloration. If you suspect membrane issues, conduct a leak test to confirm.

When replacement becomes necessary, you have two options. You can replace the entire membrane electrode assembly (MEA) or just the membrane itself.

MEA replacement is simpler but more expensive. Membrane-only replacement requires more technical skill but can be more cost-effective.

Before attempting replacement, consult your system's manual and consider professional help if you're unsure. Use only compatible replacement parts and follow proper handling procedures to avoid damaging the new membrane.

After installation, run a series of tests to verify proper functioning and best performance of your fuel cell system.

Catalyst Layer Contamination

The catalyst layer, a vital component in fuel cells, can fall victim to contamination over time. This contamination reduces the cell's efficiency and performance, potentially leading to system failure. You'll need to address this issue promptly to maintain your home fuel cell's ideal operation.

Catalyst layer contamination often stems from impurities in the fuel or air supply. These contaminants can include carbon monoxide, sulfur compounds, and particulate matter. They adhere to the catalyst surface, blocking active sites and hindering the electrochemical reactions necessary for power generation.

To combat catalyst layer contamination, you should:

- Regularly inspect and clean your fuel cell's air intake filters

- Use high-quality, purified fuel sources to minimize impurities

- Implement a periodic flushing procedure to remove accumulated contaminants

- Consider installing additional purification systems for your fuel and air supplies

If you notice a significant drop in your fuel cell's performance, it's essential to have a professional inspect the catalyst layer. They may recommend cleaning or replacement, depending on the severity of contamination.

Balance of Plant Component Issues

While the fuel cell stack is the heart of your home fuel cell system, balance of plant (BOP) components play essential supporting roles. These components include pumps, blowers, valves, heat exchangers, and control systems. When BOP issues arise, they can greatly impact your fuel cell's performance and efficiency.

Common BOP problems include pump failures, which can disrupt reactant flow and cause uneven fuel distribution. Clogged filters may restrict airflow, leading to decreased power output. Faulty valves can cause improper gas mixing or venting, potentially creating safety hazards. Heat exchanger issues may result in inadequate temperature control, affecting overall system efficiency.

To address these problems, regularly inspect and maintain your BOP components. Clean or replace filters as needed, and verify pumps are functioning correctly. Check valves for proper operation and any signs of wear. Monitor heat exchanger performance and clean it if necessary.

Keep an eye on your system's control panel for any error messages or unusual readings that might indicate BOP issues. If you're unsure about diagnosing or fixing BOP problems, don't hesitate to contact a qualified technician for assistance.

Safety System Malfunctions

Safety systems are vital components of your home fuel cell setup, designed to protect you and your property from potential hazards. When these systems malfunction, it's essential to address the issues promptly to maintain a safe operating environment.

Common safety system malfunctions include faulty gas sensors, malfunctioning emergency shut-off valves, defective pressure relief devices, and compromised ventilation systems.

To troubleshoot and fix safety system malfunctions:

- Check gas sensors regularly: Test and calibrate hydrogen and carbon monoxide detectors to verify they're functioning correctly. Replace sensors that show signs of wear or don't respond to test gases.

- Inspect emergency shut-off valves: Verify that these valves close properly when triggered. Clean or replace valves that don't seal completely or respond sluggishly.

- Examine pressure relief devices: Confirm these components aren't obstructed and can release excess pressure effectively. Replace any damaged or corroded devices immediately.

- Assess ventilation systems: Clean exhaust fans and air intakes, checking for blockages or damage. Replace filters and repair any ductwork issues to maintain proper airflow.

If you're unsure about handling these repairs, don't hesitate to contact a qualified technician.

Regular maintenance and prompt attention to safety system malfunctions will help keep your home fuel cell system operating safely and efficiently.

Maintenance Schedule Optimization

Maintaining a well-tuned home fuel cell system requires a carefully crafted maintenance schedule. You'll need to balance frequent checks with the system's operational demands to guarantee peak performance and longevity.

Start by reviewing your manufacturer's recommendations, then adjust based on your specific usage patterns and environmental factors.

Create a monthly checklist that includes inspecting connections, cleaning air filters, and checking coolant levels. Schedule quarterly tasks like testing backup batteries and calibrating sensors.

Annually, you should conduct a thorough system evaluation, including stack performance analysis and reformer efficiency tests.

Don't forget to log all maintenance activities and system performance metrics. This data will help you identify trends and optimize your schedule over time. You might find that certain components require more frequent attention in your particular setup.

Consider using a digital maintenance tracking system to set reminders and store records. This can help you stay on top of tasks and provide valuable information for technicians during servicing.

Frequently Asked Questions

How Much Does a Typical Home Fuel Cell System Cost to Install?

You can expect to pay between $20,000 and $50,000 for a typical home fuel cell system installation. The cost varies depending on the system's size, your home's energy needs, and local installation factors.

Can I Use My Existing Natural Gas Line for a Fuel Cell System?

Yes, you can typically use your existing natural gas line for a fuel cell system. You'll need to guarantee it meets the system's requirements and local regulations. It's best to consult with a professional installer for specific details.

What's the Average Lifespan of a Residential Fuel Cell System?

You can expect your residential fuel cell system to last 10-20 years on average. It'll depend on factors like maintenance, usage, and quality. Regular upkeep and proper care will help extend its lifespan considerably.

Are There Government Incentives for Installing Home Fuel Cell Systems?

Yes, you'll find various government incentives for installing home fuel cell systems. They often include tax credits, rebates, and grants at federal, state, and local levels. Check with your local energy office for specific programs in your area.

How Noisy Are Home Fuel Cell Systems During Operation?

You'll find home fuel cell systems are relatively quiet. They typically produce a low hum, similar to a refrigerator. You won't hear much noise inside your house, and it shouldn't bother your neighbors outside.

In Summary

You've now got the knowledge to tackle common home fuel cell system problems. Remember to check stack performance, electrical connections, water management, and hydrogen supply regularly. Don't forget about air flow, catalyst contamination, and balance of plant components. Always prioritize safety system checks. By optimizing your maintenance schedule, you'll keep your fuel cell running smoothly and efficiently. With these tips, you're well-equipped to handle most issues that may arise.

Leave a Reply