To enhance your masonry heater for efficient heat storage, focus on key design principles. Use dense materials like firebrick and soapstone for high thermal mass. Design a combustion chamber with a 1.5:1 height-to-width ratio for complete fuel burning. Implement a complex flue system combining vertical and horizontal paths to maximize heat transfer. Calculate fuel load capacity based on your home's heating needs, aiming for 90% heat conversion efficiency. Incorporate strategic airflow management and heat exchange channels to improve performance. Don't forget to take into account exterior surface area and insulation for ideal heat radiation. These elements are just the beginning of creating an efficient, high-performing masonry heater.

Principles of Masonry Heater Design

At the core of masonry heater design lies a set of fundamental principles that guarantee efficient heat storage and distribution.

You'll need to focus on creating a large thermal mass, typically using materials like stone, brick, or ceramics. This mass absorbs heat from a short, intense fire and slowly releases it over time.

The combustion chamber should be designed to promote complete burning of fuel, reducing emissions and maximizing heat output.

You'll want to incorporate a complex flue system that forces hot gases to travel through a series of channels within the masonry, allowing for ideal heat transfer.

Consider the overall size and shape of the heater, which should be proportional to the space it's heating.

You'll also need to make certain proper air intake and draft control to maintain efficient combustion.

Incorporate a heat-exchange surface that's large enough to effectively transfer heat to the surrounding space.

Don't forget to include clean-out access points for maintenance.

Lastly, consider the aesthetic aspects of your design, as masonry heaters often serve as focal points in living spaces.

Optimal Materials for Heat Storage

Building on the principles of masonry heater design, let's explore the ideal materials for heat storage. The key to effective heat retention lies in choosing materials with high thermal mass and conductivity.

You'll want to focus on dense materials that can absorb and store large amounts of heat energy. Firebrick is an excellent choice for the firebox and inner core due to its ability to withstand high temperatures and store heat effectively.

Surrounding this, you should consider using materials like soapstone, granite, or dense concrete. Soapstone is particularly prized for its exceptional heat retention properties and smooth, aesthetically pleasing finish.

For the outer layers, you can opt for standard brick or natural stone. These materials provide additional thermal mass while allowing for customizable exterior designs.

It's essential to avoid using materials with low thermal mass or poor conductivity, such as lightweight concrete or insulating firebrick, in heat storage areas.

Flue System Configuration

When designing your masonry heater's flue system, you'll need to contemplate vertical and horizontal configurations.

The size and length of your flues will greatly impact heat transfer efficiency and draft performance.

You'll want to balance these factors carefully to optimize your heater's overall effectiveness and safety.

Vertical vs. Horizontal Flues

Throughout the evolution of masonry heater design, the configuration of flue systems has remained a crucial factor in optimizing performance. When considering vertical vs. horizontal flues, you'll find that each option offers distinct advantages and challenges.

Vertical flues leverage natural convection, allowing hot gases to rise efficiently through the system. This configuration promotes better draft and can lead to more complete combustion. You'll often see vertical flues in traditional designs, where they're integrated seamlessly into the heater's core. They're particularly effective in taller structures and can help maintain consistent heat distribution throughout the masonry mass.

Horizontal flues, on the other hand, offer greater flexibility in design and installation. They're ideal for situations where vertical space is limited or when you need to route exhaust gases to a specific location. While horizontal flues may require additional considerations to guarantee proper draft, they can be advantageous in creating longer heat exchange pathways, potentially increasing overall efficiency.

When choosing between vertical and horizontal flues, consider your specific space constraints, desired heat output, and local building codes.

Often, the most effective masonry heater designs incorporate a combination of both vertical and horizontal flue sections to maximize heat retention and distribution.

Flue Size and Length

Flue size and length play a pivotal role in the overall performance of your masonry heater, regardless of whether you opt for vertical or horizontal configurations. The flue system's dimensions directly impact draft, heat retention, and overall efficiency.

When designing your masonry heater, you'll need to carefully consider these factors to guarantee ideal heat distribution and combustion.

To achieve the best results, keep these key points in mind:

- Flue diameter: A larger diameter allows for better draft but may reduce heat retention. Aim for a balance that suits your specific heater design and local climate conditions.

- Flue length: Longer flues increase heat absorption but may affect draft. Calculate the ideal length based on your heater's size and desired heat output.

- Bends and turns: While they can improve heat retention, too many bends may impede draft. Limit sharp turns to maintain proper airflow.

- Material choice: Select materials with high thermal mass for better heat storage and distribution.

Combustion Chamber Sizing

When sizing your masonry heater's combustion chamber, you'll need to evaluate three key factors: fuel load capacity, heat output calculations, and airflow considerations.

Your chamber's dimensions will directly impact how much wood you can burn efficiently and how much heat your heater can produce.

Remember to balance these elements carefully, ensuring adequate oxygen supply for complete combustion while maximizing the heat transfer to the surrounding masonry.

Fuel Load Capacity

Sizing the combustion chamber correctly is vital for optimizing your masonry heater's performance. The fuel load capacity directly impacts the heater's efficiency and heat output.

When designing your masonry heater, consider the following factors to determine the ideal fuel load capacity:

- Heat demand: Calculate your space's heating requirements based on square footage, insulation, and climate.

- Burn cycle duration: Decide how often you're willing to reload the heater, typically ranging from 12 to 24 hours.

- Wood species: Different wood types have varying energy densities, affecting the amount needed for a complete burn cycle.

- Emissions regulations: Confirm your fuel load capacity complies with local air quality standards.

A well-designed combustion chamber should accommodate enough wood for a complete burn cycle without overfilling. Aim for a fuel load that's 1/10th to 1/20th of the heater's total mass. This ratio guarantees efficient heat transfer and storage.

Remember that a larger fuel load doesn't always mean better performance. Overloading can lead to incomplete combustion, reduced efficiency, and increased emissions.

It's vital to strike a balance between heat output and clean burning. By carefully considering these factors, you'll optimize your masonry heater's fuel load capacity for maximum efficiency and comfort.

Heat Output Calculations

Precision in heat output calculations is essential for properly sizing your masonry heater's combustion chamber. You'll need to take into account several factors to determine the best heat output for your space. Start by calculating your home's heat loss rate, factoring in insulation, windows, and climate. This will help you determine the BTU requirements for your living area.

Next, assess the heater's efficiency and heat storage capacity. A well-designed masonry heater can achieve up to 90% efficiency, converting most of the fuel's energy into usable heat. Reflect on the following factors when calculating heat output:

| Factor | Calculation Method |

|---|---|

| Fuel type | BTU content per unit |

| Burn rate | Kg of fuel consumed per hour |

| Combustion efficiency | Percentage of fuel energy utilized |

| Heat transfer rate | BTU transferred to masonry mass |

| Heat release rate | BTU released to room over time |

To improve your heater's performance, you'll want to balance the fuel load capacity with the desired heat output. This guarantees that your masonry heater provides consistent warmth without overheating the space. Remember to account for the thermal mass of your heater, as it will continue to radiate heat long after the fire has died down.

Airflow Considerations

Proper airflow is essential to dialing in your masonry heater's performance. When designing your combustion chamber, you'll need to carefully consider its size and shape to guarantee ideal airflow. A well-designed chamber promotes complete combustion, reduces emissions, and maximizes heat transfer to the masonry mass.

To achieve ideal airflow in your masonry heater, focus on these key factors:

- Combustion chamber dimensions: Aim for a height-to-width ratio of about 1.5:1 to create a tall, narrow space that encourages efficient burning.

- Air intake placement: Position primary air inlets at the base of the firebox to supply oxygen to the fuel bed, and secondary air inlets higher up to promote complete combustion of gases.

- Flue size and configuration: Design your flue system to maintain proper draft without excessive heat loss. A too-large flue can lead to poor performance and heat waste.

- Baffle placement: Incorporate strategically placed baffles to slow down hot gases, increasing their residence time in the heater and improving heat transfer.

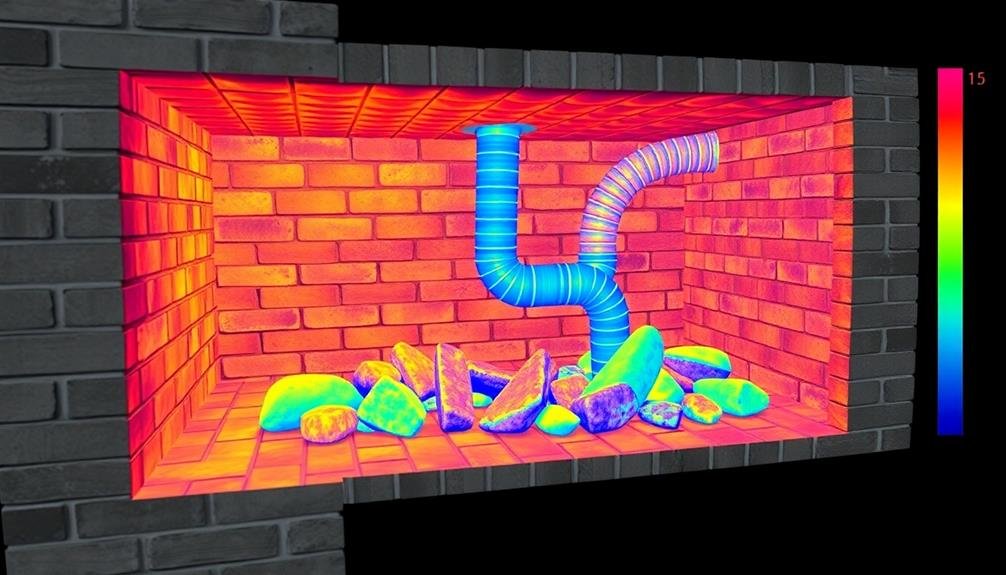

Heat Exchange Channels

The intricate network of heat exchange channels forms the core of an efficient masonry heater. These channels are designed to maximize heat transfer from the combustion gases to the masonry mass. You'll want to create a labyrinthine path that forces the hot gases to travel a longer distance before exiting, allowing more time for heat absorption.

When designing these channels, consider their size and shape carefully. Narrower channels increase gas velocity, enhancing heat transfer, but they can also lead to higher draft resistance. You'll need to strike a balance between these factors.

Incorporate sudden changes in direction and cross-sectional area to create turbulence, which further improves heat exchange. The material lining these channels is essential. Use refractory bricks or castable refractory cement to withstand high temperatures and maximize heat absorption.

You should also consider adding heat exchange fins or baffles within the channels to increase surface area and improve efficiency. Remember to design for easy cleaning and maintenance. Include access points that allow you to remove any accumulated soot or debris, ensuring peak performance over time.

Exterior Surface Area Considerations

Maximizing exterior surface area is vital for efficient heat distribution in a masonry heater. The larger the surface area, the more heat can be radiated into your living space. Contemplate incorporating fins, contours, or textured surfaces to increase the overall exterior area without greatly increasing the heater's footprint.

When designing your masonry heater's exterior, keep these factors in mind:

- Material choice: Different materials have varying heat conductivity and retention properties. Choose materials that balance aesthetics with thermal performance.

- Surface texture: Rough or uneven surfaces can increase the effective surface area, potentially improving heat distribution.

- Color: Darker surfaces tend to absorb and radiate heat more effectively than lighter ones.

- Shape: Curved or angled surfaces can help direct heat into specific areas of your room.

You'll want to strike a balance between maximizing surface area and maintaining an aesthetically pleasing design.

Remember that excessive surface area can lead to rapid heat loss, potentially reducing the heater's overall efficiency. It's vital to evaluate your specific heating needs and the layout of your space when optimizing the exterior surface area of your masonry heater.

Insulation Strategies for Efficiency

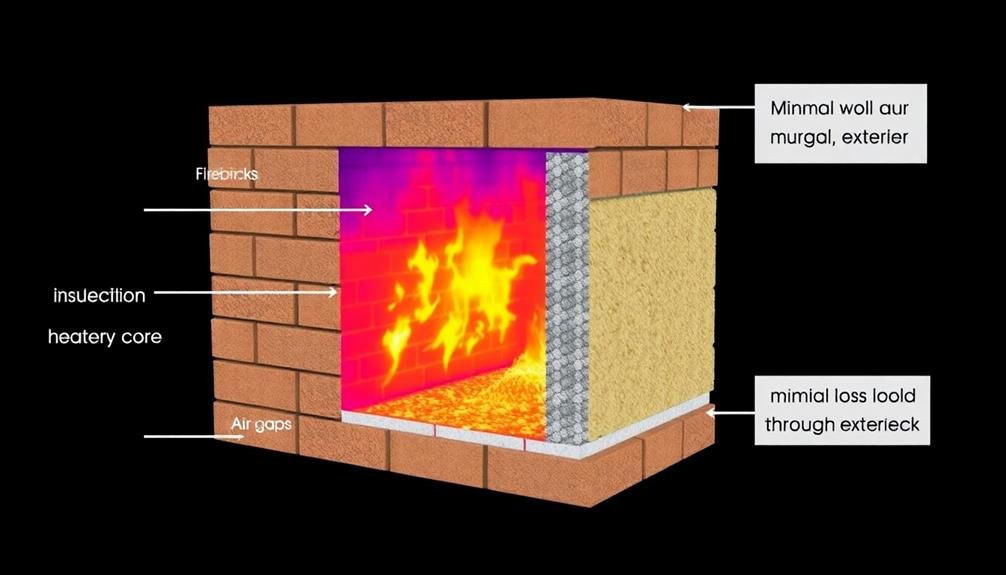

While surface area plays a key role in heat distribution, insulation is equally important for maintaining your masonry heater's efficiency. You'll want to focus on two main areas: the heater core and the surrounding space.

For the heater core, use high-temperature insulation materials like ceramic fiber blankets or refractory bricks. These materials help retain heat within the core, allowing for more efficient heat storage and slower release. Place insulation between the inner and outer walls of the heater, creating a thermal barrier that reduces heat loss to the exterior.

In the surrounding space, consider insulating the floor beneath the heater to prevent heat from escaping downward. You can use a layer of fire-resistant insulation board or create an air gap using a raised platform.

Don't forget to insulate nearby walls and the ceiling above the heater to maximize heat retention in the room.

When designing your masonry heater, factor in proper air gaps and ventilation to prevent overheating. Use heat-resistant sealants to close any gaps in the insulation layers, ensuring a continuous thermal barrier.

Airflow Management Techniques

In addition to proper insulation, effective airflow management is essential for maximizing your masonry heater's performance.

You'll want to focus on creating a balanced system that guarantees efficient combustion and heat distribution throughout your living space. To achieve this, consider implementing a series of baffles and channels within the heater's core to extend the path of hot gases, enhancing heat transfer to the masonry mass.

Pay close attention to your heater's air intake and exhaust systems. A well-designed air intake will provide adequate oxygen for combustion, while a properly sized chimney will efficiently remove smoke and gases.

You can further enhance airflow management by:

- Installing a bypass damper to improve draft during startup

- Using secondary air inlets to promote complete combustion

- Incorporating a heat exchanger to capture additional heat from exhaust gases

- Implementing a clean-out system to maintain peak airflow over time

Integration With Home Architecture

Your masonry heater's integration with your home's architecture is essential for both aesthetic appeal and functional efficiency. When planning the installation, consider the heater's placement carefully. Ideally, position it centrally to maximize heat distribution throughout your living spaces.

You'll want to guarantee it complements your home's interior design while adhering to safety codes and clearance requirements.

Customize the heater's exterior to match your home's style. Choose materials and finishes that blend seamlessly with your existing décor, such as brick, stone, or tiles. You can incorporate built-in seating or storage around the heater to maximize space utilization.

Don't forget to plan for proper ventilation and chimney integration, which may affect your roof design.

Consider the heater's impact on your floor plan. Its substantial size may influence traffic flow and furniture arrangement. You might need to reinforce your floor to support the heater's weight, especially in older homes.

Additionally, think about how the heater will interact with your home's existing heating system. You may be able to reduce reliance on conventional heating methods, potentially affecting your HVAC layout and energy consumption patterns.

Frequently Asked Questions

How Long Does It Take to Build a Masonry Heater?

You'll need to set aside about 1-2 weeks to build a masonry heater. It's a complex project that requires careful planning, skilled labor, and proper curing time. Don't rush it; quality construction guarantees peak performance.

What Is the Typical Lifespan of a Well-Maintained Masonry Heater?

You'll find that a well-maintained masonry heater can last an impressive 50 to 100 years or more. With proper care, it'll serve you for generations. Regular inspections and minor repairs will guarantee its longevity and continued efficiency.

Can Masonry Heaters Be Retrofitted Into Existing Homes?

Yes, you can retrofit masonry heaters into existing homes. You'll need to assess your space, consider structural requirements, and plan for proper ventilation. It's a complex project, so you'll likely want to hire a professional for installation.

Are There Any Safety Concerns Specific to Masonry Heaters?

You'll need to be aware of potential safety concerns with masonry heaters. These include carbon monoxide risks, proper ventilation, and fire hazards. It's essential to have professional installation and regular maintenance to guarantee safe operation in your home.

How Do Masonry Heaters Compare to Other Heating Systems in Cost-Effectiveness?

You'll find masonry heaters are more cost-effective in the long run. They're pricier upfront but use less fuel and provide consistent heat. You'll save money over time compared to traditional heating systems.

In Summary

You've learned the key elements of optimizing masonry heater design for efficient heat storage. By carefully considering materials, flue configuration, combustion chamber size, heat channels, surface area, insulation, and airflow, you'll create a highly effective heating system. Don't forget to integrate the heater seamlessly with your home's architecture. With these principles in mind, you're well-equipped to design or select a masonry heater that'll provide long-lasting, efficient warmth for your living space.

Leave a Reply