Proper water balance in your home's fuel cell system is essential for peak performance and longevity. It affects electrical efficiency, power output, and system durability. Maintaining the right balance prevents membrane dehydration and electrode flooding, ensuring stable operation under varying conditions. It also maximizes fuel utilization, reduces maintenance costs, and extends the system's lifespan from 5-8 years to 10-15 years. Proper water management enhances energy efficiency, minimizes emissions, and integrates smoothly with your home's existing water systems. By understanding and maintaining water balance, you'll enhance your fuel cell's performance and environmental benefits. Exploring this topic further will reveal additional advantages for your home energy solution.

Understanding Fuel Cell Water Balance

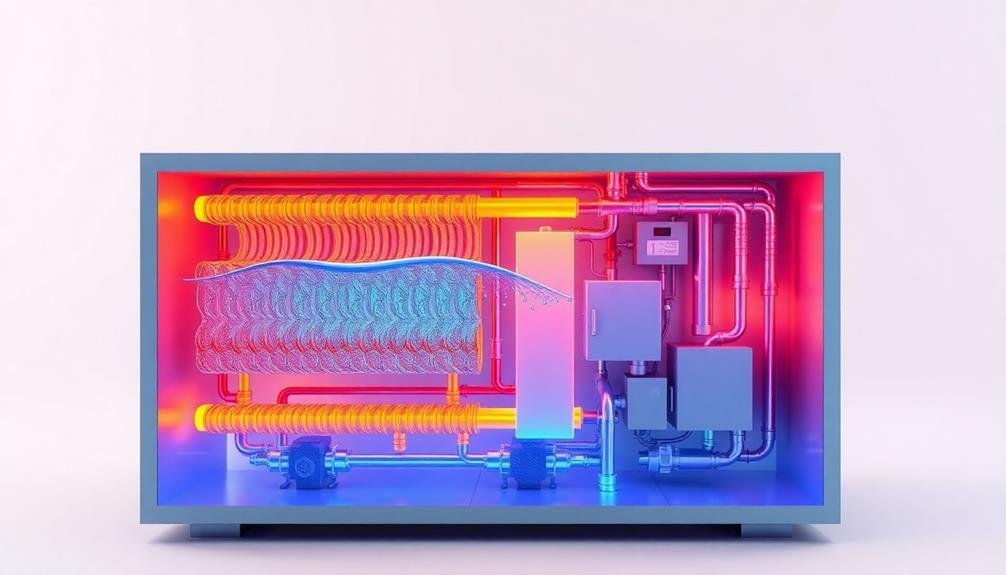

The concept of water balance in fuel cells is vital for their efficient operation in home systems. You'll need to understand that fuel cells produce electricity through an electrochemical reaction between hydrogen and oxygen, with water as a byproduct. Maintaining the right amount of water is essential for peak performance.

Too much water can flood the cell, blocking gas diffusion channels and reducing efficiency. On the other hand, too little water can dry out the membrane, hindering proton conductivity. You'll want to achieve a delicate balance where there's enough water to keep the membrane hydrated but not so much that it impedes gas flow.

Factors affecting water balance include operating temperature, pressure, and current density. You'll need to take into account humidity levels in both the anode and cathode streams.

Water management strategies often involve using hydrophobic and hydrophilic materials in different cell components. You might also employ water recovery systems to recycle produced water back into the fuel cell.

Understanding water balance helps you enhance your home fuel cell system's efficiency, durability, and overall performance. It's a significant aspect of fuel cell technology that you can't afford to overlook.

Efficiency and Performance Impacts

Numerous efficiency and performance impacts stem from proper water balance in home fuel cell systems. When you maintain the right water balance, you'll see improved electrical efficiency, as the ideal hydration of the membrane allows for better proton conductivity. This means you'll get more power output for the same amount of fuel input.

You'll also notice enhanced durability and longevity of your fuel cell stack. Proper hydration prevents membrane degradation and reduces the risk of mechanical stress on components. This translates to fewer replacements and lower maintenance costs over time.

Additionally, you'll experience more stable operation across varying load conditions. A well-balanced system can respond quickly to changes in power demand without compromising performance. You'll avoid issues like flooding or drying out, which can lead to voltage instability or even system shutdowns.

Proper water balance also improves fuel utilization efficiency. It guarantees that reactant gases can effectively reach catalytic sites, maximizing the conversion of chemical energy to electrical energy. This means you'll get more value from your fuel and reduce waste.

Preventing Membrane Dehydration

To prevent membrane dehydration, you'll need to implement several key strategies. First, maintain proper humidification levels in your fuel cell system. You can achieve this by using a humidifier or incorporating a water recovery system that recycles water produced during the electrochemical reaction. It's essential to monitor and control the dew point of both the anode and cathode gas streams to guarantee ideal water content.

Next, enhance your system's operating temperature. Higher temperatures increase the risk of dehydration, so you'll want to find a balance that maximizes performance without compromising membrane hydration. Consider implementing temperature sensors and a control system to maintain perfect conditions.

You should also pay attention to gas flow rates. Excessive flow can strip water from the membrane, so adjust your system to provide sufficient reactants without causing dehydration. Additionally, incorporate pressure regulators to maintain appropriate back pressure, which helps retain water within the cell.

Lastly, choose membrane materials with enhanced water retention properties. Modern polymer electrolyte membranes often include hydrophilic additives or modified chemical structures that improve water management capabilities, reducing the risk of dehydration and extending the life of your fuel cell system.

Avoiding Electrode Flooding

Water management is a delicate balancing act in fuel cell systems. While preventing membrane dehydration is vital, you must also be vigilant about avoiding electrode flooding. This occurs when excess water accumulates in the electrode layers, blocking the pores and hindering reactant gas diffusion.

To avoid electrode flooding, you'll need to implement effective water removal strategies. First, guarantee proper gas flow rates through the fuel cell channels. This helps sweep away excess water droplets.

You can also optimize the cell's operating temperature, as higher temperatures promote water evaporation. Consider using hydrophobic coatings on gas diffusion layers to repel water and maintain open pathways for reactants.

Monitor the fuel cell's performance closely. If you notice a sudden drop in voltage or current output, it could indicate electrode flooding. In such cases, you may need to temporarily increase gas flow rates or adjust operating conditions to remove excess water.

Implementing a purge cycle can also help clear accumulated water from the electrodes.

Optimizing Heat Management

To enhance heat management in home fuel cell systems, you'll need to focus on thermal distribution efficiency.

You can achieve this by strategically placing components and utilizing advanced insulation materials.

Integrating an efficient cooling system is essential, as it helps maintain ideal operating temperatures and prevents performance degradation due to overheating.

Thermal Distribution Efficiency

While fuel cells generate electricity efficiently, they also produce heat that must be managed carefully. In home systems, thermal distribution efficiency plays a vital role in maximizing overall performance. You'll want to guarantee that the heat produced is distributed evenly and utilized effectively throughout your living space.

To improve thermal distribution efficiency, consider implementing a well-designed heat recovery system. This will capture excess heat from the fuel cell and redirect it to areas where it's needed most, such as for space heating or domestic hot water.

You'll also benefit from using insulated piping and minimizing heat loss in the distribution network. Smart controls can further enhance efficiency by adjusting heat flow based on demand and outdoor temperatures.

You might integrate your fuel cell system with a radiant floor heating setup or low-temperature radiators for peak heat distribution. Don't forget to balance the system regularly to guarantee even heat distribution across all zones.

Cooling System Integration

Effective heat management in fuel cell home systems goes beyond distribution; it also involves integrating a robust cooling system. You'll need to take into account how the cooling system interacts with your fuel cell's water balance. A well-designed cooling system helps maintain ideal operating temperatures, preventing overheating and ensuring efficient performance.

When integrating a cooling system, you should focus on two key aspects: heat removal and water management. The cooling system must efficiently remove excess heat generated by the fuel cell, while also managing the water produced as a byproduct of the electrochemical reaction.

You'll want to use a combination of air and liquid cooling methods to achieve this balance. Think about implementing a closed-loop liquid cooling system that circulates coolant through the fuel cell stack. This approach allows for precise temperature control and helps recover water vapor.

Additionally, incorporate air cooling for auxiliary components and to assist with water vapor condensation. By enhancing the cooling system integration, you'll improve overall system efficiency, extend the fuel cell's lifespan, and maintain proper water balance.

Remember to factor in the local climate and your home's specific heating and cooling needs when designing the integrated system.

Durability and Lifespan Considerations

Durability and lifespan are vital factors when considering fuel cell systems for home use. You'll want a system that can withstand the rigors of daily operation while maintaining its efficiency over time. Proper water balance plays a key role in achieving this longevity.

When your fuel cell system maintains ideal water balance, it prevents membrane degradation and catalyst poisoning. These issues can greatly reduce your system's performance and lifespan. You'll also avoid problems like flooding or drying out of the membrane, which can lead to irreversible damage.

To emphasize the impact of water balance on durability, consider the following:

| Water Balance | Membrane Health | System Lifespan |

|---|---|---|

| Ideal | Excellent | 10-15 years |

| Slightly Off | Good | 8-12 years |

| Poor | Fair | 5-8 years |

| Severe Imbalance | Poor | 2-5 years |

Water Recycling in Fuel Cells

Water recycling is a cornerstone of efficient fuel cell operation in home systems. When your fuel cell generates electricity, it produces water as a byproduct. Instead of simply discarding this water, you can recycle it to maintain the system's water balance and improve overall efficiency.

In a well-designed home fuel cell system, you'll find a water management subsystem that collects, purifies, and redistributes the produced water. This recycling process helps you reduce water consumption and minimizes waste. You'll typically see a closed-loop system where water is continuously reused, requiring only occasional top-ups to compensate for small losses.

The recycled water serves multiple purposes within your fuel cell. It's used for cooling, humidifying the incoming air, and maintaining proper membrane hydration. By recycling water, you're ensuring maximum performance and extending the lifespan of your fuel cell stack.

You'll need to monitor the water quality regularly, as impurities can accumulate over time. Periodic maintenance of the water recycling system, including filter replacements and purification treatments, will help you maintain peak efficiency and prevent potential damage to your fuel cell components.

Humidity Control Mechanisms

You'll find that humidity control in fuel cell home systems relies on several key mechanisms.

Membrane hydration management guarantees ideal proton conductivity, while condensation removal systems prevent water buildup that could impede performance.

Reactant gas humidification helps maintain the right moisture balance, supporting efficient fuel cell operation in your home.

Membrane Hydration Management

While maintaining proper membrane hydration is essential for ideal fuel cell performance, it's a delicate balancing act that requires sophisticated humidity control mechanisms.

You'll need to guarantee that the polymer electrolyte membrane (PEM) remains adequately hydrated to facilitate proton conduction, but not so wet that it floods.

To manage membrane hydration effectively, you'll employ various techniques. First, you'll control the humidification of incoming reactant gases, typically using humidifiers or water injection systems.

You'll also monitor and adjust the operating temperature, as higher temperatures increase water evaporation.

You'll implement water recovery systems to capture and recycle product water, reducing the need for external humidification.

Additionally, you'll optimize flow field designs to promote uniform water distribution across the membrane.

You may use microporous layers or hydrophobic coatings on gas diffusion layers to manage water transport.

Pressure differentials across the membrane can also help control water movement.

Condensation Removal Systems

Inevitably, excess water accumulation in fuel cell systems necessitates robust condensation removal mechanisms.

You'll find that these systems play an essential role in maintaining ideal performance and longevity of your home fuel cell unit.

Condensation removal systems typically employ a combination of gravity-assisted drainage and active water extraction methods.

You'll notice that many designs incorporate sloped channels or collection trays to guide water droplets towards designated exit points.

These pathways are often equipped with hydrophobic coatings to enhance water flow and prevent blockages.

For more efficient water management, you might encounter systems using small pumps or fans to actively remove condensation.

These components work in tandem with sensors that monitor humidity levels and trigger removal processes when necessary.

Some advanced systems even incorporate porous materials or wicking fabrics to absorb excess moisture and facilitate its removal.

You'll appreciate that effective condensation removal not only prevents flooding and corrosion but also helps maintain the delicate water balance required for ideal fuel cell operation.

Reactant Gas Humidification

In addition to removing excess water, maintaining proper humidity levels in the reactant gases is crucial for optimal fuel cell performance.

You'll need to implement effective humidification mechanisms to guarantee ideal water content in both the hydrogen and oxygen streams entering the fuel cell.

For the hydrogen side, you can use a bubble humidifier or a membrane-based humidifier.

Bubble humidifiers pass the dry gas through water, picking up moisture along the way. Membrane humidifiers use a water-permeable membrane to transfer moisture from a wet stream to the dry gas.

On the oxygen side, you'll typically humidify the incoming air. This can be done using similar methods as the hydrogen side, or by recirculating some of the moist exhaust air back into the inlet stream.

You'll need to carefully control the humidity levels to prevent both flooding and drying out of the membrane.

Too much moisture can block gas diffusion channels, while too little can dry out the membrane, reducing proton conductivity.

Sensors and control systems help maintain the right balance, adjusting humidification based on operating conditions like temperature and current density.

Cold Weather Operation Challenges

Fuel cells' operation in cold weather presents unique challenges for maintaining proper water balance. When temperatures drop, you'll face increased risks of water freezing within the fuel cell system. This can lead to ice formation in critical components, potentially damaging membranes, gas diffusion layers, and flow channels.

Frozen water can also block reactant gas flow, reducing overall system efficiency and performance. You'll need to implement specific strategies to prevent these issues. Consider using thermal insulation to protect sensitive components and maintain operating temperatures above freezing.

Implementing heating elements or waste heat recovery systems can help warm incoming gases and prevent ice formation. You may also need to adjust your system's purge cycles to remove excess water more frequently, reducing the risk of freezing.

Another challenge you'll encounter is reduced membrane hydration at lower temperatures. This can decrease proton conductivity and overall fuel cell efficiency. To combat this, you might need to increase humidification levels of incoming gases or adjust your control strategies to maintain ideal membrane hydration.

Maintenance and Monitoring Requirements

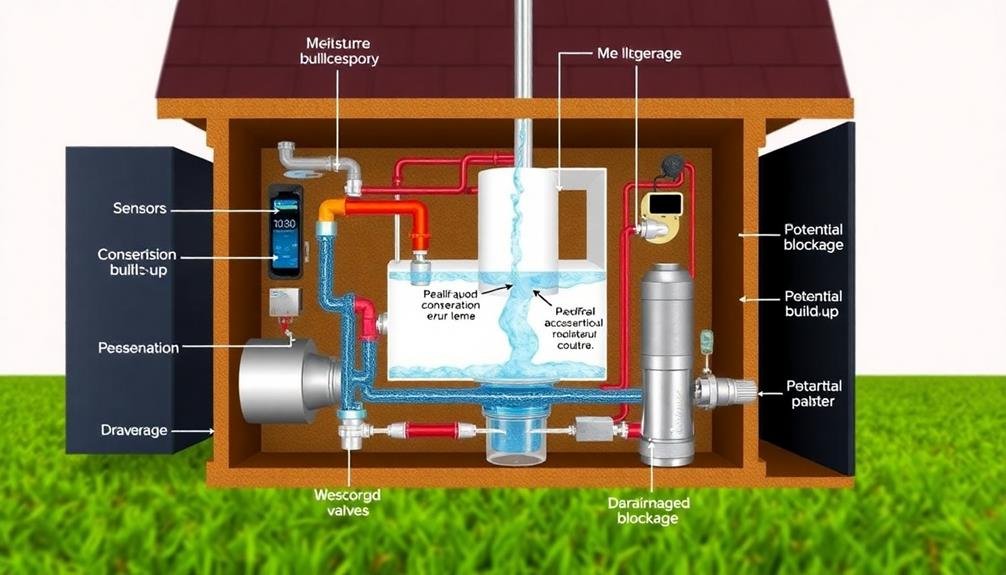

Maintaining proper water balance in fuel cell systems requires ongoing attention and care. You'll need to regularly monitor and adjust water levels to guarantee peak performance and longevity of your home fuel cell system. This involves checking condensate collection, humidity sensors, and water quality indicators.

To effectively maintain your fuel cell's water balance, you should:

- Inspect water collection tanks weekly, emptying them as needed to prevent overflow.

- Clean or replace air filters monthly to reduce contaminants entering the system.

- Test water quality quarterly, adjusting purification systems if necessary.

- Calibrate humidity sensors annually to guarantee accurate readings.

You'll also want to keep an eye on your system's performance metrics, such as power output and efficiency. Any sudden changes could indicate water balance issues. It's vital to address these promptly to prevent damage to the fuel cell stack or other components.

Consider setting up automated alerts for critical parameters, allowing you to respond quickly to potential problems.

Integration With Home Water Systems

When integrating a fuel cell system with your home's water infrastructure, you'll need to assess plumbing connections and guarantee compatibility with existing pipes and fixtures.

You'll also want to evaluate your water quality, as impurities can affect fuel cell performance and longevity.

Additionally, you must implement appropriate waste management solutions to handle any byproducts or excess water produced by the fuel cell system.

Plumbing Connections and Compatibility

Integrating fuel cell systems with existing home plumbing requires careful consideration of connection points and compatibility issues.

You'll need to guarantee that your fuel cell's water management system can seamlessly interface with your home's water supply and disposal networks. This involves evaluating your current plumbing setup and making necessary modifications to accommodate the fuel cell's unique requirements.

When planning your fuel cell integration, consider these key factors:

- Water quality: Your fuel cell may require filtered or purified water, necessitating the installation of additional treatment systems.

- Pressure regulation: Fuel cells often operate at specific water pressures, so you might need to install pressure regulators or booster pumps.

- Drainage systems: Excess water produced by the fuel cell must be safely disposed of, potentially requiring new drain lines or modifications to existing ones.

- Backflow prevention: To protect your home's potable water supply, you'll need to install appropriate backflow prevention devices.

It's vital to work with a qualified plumber or fuel cell specialist who understands the specific requirements of your system.

They can help you navigate local building codes, guarantee proper installation, and maintain the integrity of both your fuel cell and home plumbing systems.

Water Quality Considerations

Water quality plays a central role in the successful integration of fuel cell systems with home water networks. You'll need to assess the purity of water entering and exiting your fuel cell system to guarantee peak performance and longevity.

Most fuel cells require high-purity water to function efficiently. Your home's tap water likely contains minerals and impurities that can damage fuel cell components over time. To address this, you'll need to install a water treatment system, such as reverse osmosis or deionization, to purify the water before it enters the fuel cell.

On the output side, the water produced by fuel cells is typically very pure. However, it may be too pure for direct use in your home's plumbing system. You might need to remineralize this water or blend it with tap water to prevent corrosion of pipes and appliances.

Regular water quality testing is essential to maintain the balance between fuel cell requirements and your home's water system.

You'll want to monitor pH levels, mineral content, and conductivity to guarantee both systems operate harmoniously. By addressing these water quality assessments, you'll maximize the efficiency and lifespan of your integrated fuel cell system.

Waste Management Solutions

Effective waste management is essential when integrating fuel cell systems with your home's water network.

You'll need to address the disposal of excess water produced by the fuel cell, which may contain trace contaminants. To guarantee proper handling of this byproduct, you should consider implementing an all-encompassing waste management strategy.

Here are four key solutions to manage fuel cell waste water effectively:

- Install a dedicated drainage system: This separate network will prevent mixing with your regular wastewater and allow for proper treatment before disposal.

- Implement a water recycling system: Purify and reuse the fuel cell's water output for non-potable applications like irrigation or toilet flushing.

- Use a neutralization tank: This will help balance the pH levels of the waste water before it enters the main sewage system or undergoes further treatment.

- Incorporate a filtration system: Remove any remaining impurities or contaminants from the fuel cell's water output to meet local environmental regulations.

Environmental Benefits of Proper Balance

Proper water balance in fuel cell home systems offers three key environmental benefits. First, it maximizes energy efficiency, reducing overall fuel consumption and greenhouse gas emissions. You'll get more power from less fuel, minimizing your carbon footprint. Second, it extends the lifespan of your fuel cell system, reducing the need for replacement parts and decreasing electronic waste. Finally, it optimizes water usage, preventing unnecessary water consumption or waste.

To understand the impact of proper water balance, consider these comparisons:

| Aspect | Balanced System | Unbalanced System |

|---|---|---|

| Efficiency | 90-95% | 70-80% |

| Lifespan | 10-15 years | 5-8 years |

| Water Usage | Minimal waste | Excess consumption |

| Emissions | Low | Higher |

Troubleshooting Common Water Issues

While maintaining proper water balance is ideal, you may encounter issues that disrupt your fuel cell's performance. Recognizing and addressing these problems quickly can help maintain efficiency and extend your system's lifespan. Common water-related issues include flooding, dehydration, and uneven water distribution.

To troubleshoot water balance problems in your home fuel cell system:

- Monitor water levels regularly: Check the water reservoir and drainage systems to verify proper levels are maintained. Look for signs of overflow or insufficient water supply.

- Inspect for leaks: Examine connections, seals, and membranes for any signs of water leakage. Even small leaks can greatly impact your fuel cell's performance.

- Adjust humidification settings: If your system allows, fine-tune the humidification parameters to optimize water balance. This may involve adjusting temperature or flow rates.

- Clean and maintain components: Regularly clean filters, membranes, and water management components to prevent clogs and verify proper water flow.

If you're unable to resolve water balance issues on your own, don't hesitate to consult a professional. They can diagnose more complex problems and recommend appropriate solutions to keep your fuel cell system operating efficiently.

Frequently Asked Questions

How Do Fuel Cells Compare to Other Home Energy Systems in Water Usage?

You'll find fuel cells generally use less water than traditional power plants. They're more efficient, producing water as a byproduct. However, they still require some water for cooling, unlike solar panels which don't need water at all.

Can Excess Water From Fuel Cells Be Used for Household Purposes?

You can't use excess water from fuel cells for household purposes. It's not safe for consumption or general use. The water produced is typically recycled within the system or disposed of properly due to potential contaminants.

What Are the Noise Levels Associated With Fuel Cell Water Management Systems?

You'll find that fuel cell water management systems generally operate quietly. They don't produce much noise, as they mostly involve passive components. You're unlikely to notice any significant sound from these systems in your home.

Are There Any Safety Concerns Related to Water Production in Home Fuel Cells?

You should be aware of potential safety concerns with home fuel cells' water production. These include flooding risks, water quality issues, and potential freezing in cold climates. It's important to properly maintain and monitor your system to prevent problems.

How Do Regional Water Quality Differences Affect Fuel Cell System Performance?

You'll find that regional water quality differences can impact your fuel cell's performance. Hard water may cause scaling, while contaminants can poison catalysts. You'll need proper water treatment systems to guarantee peak efficiency and longevity of your fuel cell.

In Summary

You've now seen why water balance is essential for your home fuel cell system. It's not just about efficiency—it affects performance, longevity, and environmental impact. By maintaining proper balance, you'll prevent membrane damage, optimize heat management, and reduce maintenance needs. Remember to monitor your system regularly and integrate it wisely with your home's water setup. With proper care, you'll enjoy reliable, clean energy while minimizing your environmental footprint.

Leave a Reply