To seal solar panel connections against water, you'll primarily use silicone-based sealants, butyl tape, or weatherproof junction boxes. Silicone sealants offer durability and UV resistance, while butyl tape provides flexibility for temperature changes. Weatherproof junction boxes with high IP ratings protect internal connections. It's vital to clean surfaces thoroughly before applying any sealant. Regular maintenance and inspections guarantee long-lasting protection. Climate considerations, such as temperature fluctuations and UV exposure, should guide your sealant choice. Whether you opt for professional installation or a DIY approach, proper application techniques are essential for effective waterproofing. Explore further to uncover the nuances of each method and make the best choice for your solar setup.

Importance of Waterproof Connections

When it comes to solar panel installations, waterproof connections are vital. You'll want to guarantee that your solar system remains protected from moisture intrusion, which can lead to numerous problems.

Water seeping into electrical connections can cause short circuits, corrosion, and degradation of components, ultimately reducing your system's efficiency and lifespan. Properly sealed connections prevent these issues, maintaining the integrity of your solar array.

They'll shield sensitive electrical components from rain, snow, humidity, and other environmental factors that could compromise performance. You'll also minimize the risk of electrical fires and avoid costly repairs or replacements.

Waterproof connections are essential for safety compliance and meeting local building codes. They'll help your system withstand harsh weather conditions and temperature fluctuations, guaranteeing consistent power generation throughout the year.

By investing in high-quality waterproof seals, you're protecting your solar investment and maximizing its long-term value.

Don't underestimate the importance of proper sealing techniques. Even small gaps or imperfections can allow moisture to penetrate, potentially causing significant damage over time.

Always use appropriate materials and methods to create a reliable barrier against water intrusion, safeguarding your solar panel connections for years to come.

Types of Solar Panel Sealants

When sealing your solar panel connections, you'll encounter several types of sealants designed for this specific purpose.

The most common options include silicone-based sealant products, epoxy resin compounds, and polyurethane sealing materials.

Each type offers unique properties and advantages, making it essential to choose the right sealant for your particular solar panel setup and environmental conditions.

Silicone-Based Sealant Products

Among the various types of solar panel sealants, silicone-based products stand out for their durability and versatility.

You'll find that these sealants offer excellent resistance to UV radiation, extreme temperatures, and moisture, making them ideal for outdoor applications like solar panel installations.

When choosing a silicone-based sealant for your solar panels, look for products specifically designed for photovoltaic systems. These often come in clear or white formulations to blend seamlessly with your panels.

Some popular options include Dow Corning's 732 Multi-Purpose Sealant and GE's Silicone II Window & Door Sealant.

You'll appreciate that silicone sealants are easy to apply and typically cure within 24 to 48 hours. They maintain their flexibility over time, allowing for the natural expansion and contraction of solar panel components due to temperature fluctuations.

It's important to note that while silicone-based sealants excel in many aspects, they may not adhere well to certain plastics.

In such cases, you might need to use a primer or consider alternative sealant types. Always check the manufacturer's recommendations for compatibility with your specific solar panel materials before application.

Epoxy Resin Compounds

In addition to silicone-based sealants, epoxy resin compounds offer another robust solution for sealing solar panel connections. These two-part adhesives consist of a resin and a hardener that, when mixed, create a strong, waterproof bond. Epoxy resins are known for their excellent adhesion to various materials, including metal, glass, and plastic, making them ideal for solar panel applications.

You'll find that epoxy resins provide superior chemical resistance and can withstand extreme temperatures, ensuring long-lasting protection for your solar panel connections. They're also highly resistant to UV radiation, which is vital for outdoor installations exposed to constant sunlight.

When applying epoxy resin compounds, you'll need to carefully mix the two components according to the manufacturer's instructions. The resulting mixture typically has a limited working time, so you'll need to work quickly and efficiently.

Once cured, epoxy resin forms a hard, durable seal that's difficult to remove, providing excellent protection against moisture intrusion.

While epoxy resins offer impressive sealing capabilities, they're generally less flexible than silicone-based sealants. This characteristic makes them less suitable for applications where movement or vibration is expected.

However, for static connections, epoxy resins provide unmatched strength and durability.

Polyurethane Sealing Materials

Another effective option for sealing solar panel connections is polyurethane-based materials. These versatile sealants offer excellent durability and flexibility, making them ideal for withstanding the harsh environmental conditions that solar panels face. You'll find polyurethane sealants in various forms, including liquid, paste, and tape.

When choosing a polyurethane sealant for your solar panel connections, consider the following key properties:

| Property | Importance | Typical Range |

|---|---|---|

| UV Resistance | High | 5-10 years |

| Elongation | Medium | 300-800% |

| Cure Time | Low | 24-72 hours |

Polyurethane sealants excel in adhering to multiple surfaces, including glass, metal, and plastic. This makes them particularly useful for sealing diverse components in solar panel systems. They're also known for their resistance to weathering, chemicals, and temperature fluctuations.

You'll need to apply polyurethane sealants carefully, guaranteeing a clean surface and following the manufacturer's instructions. While they may take longer to cure than some alternatives, the resulting seal is often more robust and long-lasting. Remember to choose a product specifically designed for outdoor use in solar applications to guarantee peak performance.

Silicon-Based Sealants for Solar Panels

Silicon-based sealants for solar panels come in various types, including room temperature vulcanizing (RTV) silicone and high-temperature silicone adhesives.

You'll find these sealants are typically applied using caulking guns or manual dispensers, ensuring precise and even coverage.

These sealants offer excellent durability and longevity, often lasting for decades while withstanding extreme temperatures, UV radiation, and moisture exposure.

Types of Silicon Sealants

Delving into the world of silicon-based sealants for solar panels reveals a variety of options tailored to different needs and environmental conditions.

You'll find two main categories: one-component and two-component sealants.

One-component sealants are ready to use straight from the tube. They cure when exposed to air or moisture, making them convenient for quick applications. RTV (Room Temperature Vulcanizing) silicone is a popular choice in this category, offering excellent adhesion and flexibility.

Two-component sealants require mixing before application. They typically provide stronger bonds and faster curing times. These are ideal for larger projects or when you need a more robust seal.

Within these categories, you'll encounter specific types:

- Neutral-cure silicones: These don't release corrosive byproducts, making them safe for most substrates.

- Acetoxy silicones: They cure quickly but can corrode certain metals.

- Modified silicones: These combine silicone properties with other materials for enhanced performance.

- UV-resistant silicones: Specially formulated to withstand prolonged sun exposure.

When choosing a sealant, consider factors like curing time, temperature resistance, and compatibility with your solar panel materials.

Always check the manufacturer's recommendations to ascertain you're using the right product for your specific application.

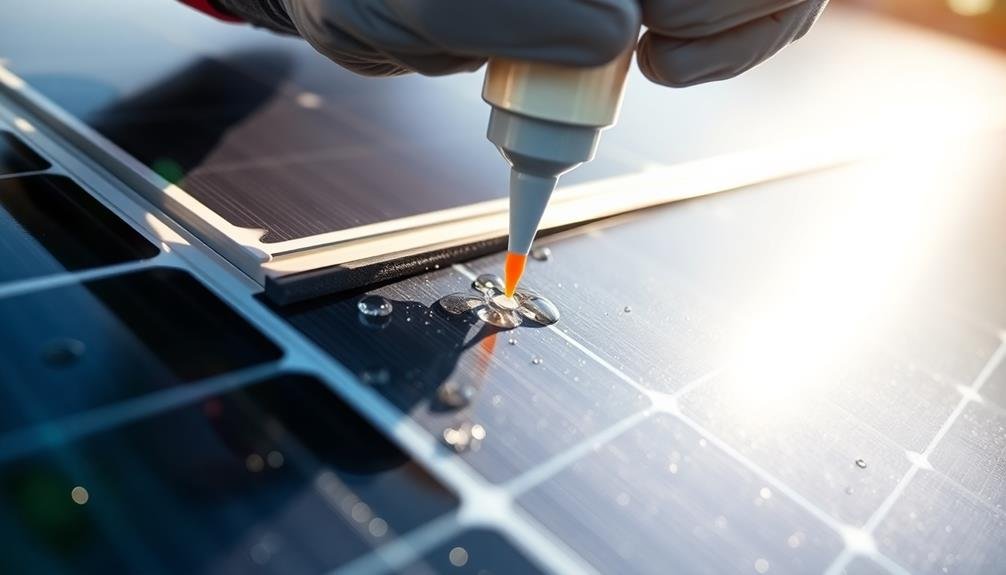

Application Methods

Having chosen the right silicon-based sealant for your solar panel project, it's time to focus on how to apply it effectively.

Begin by cleaning the surfaces thoroughly with isopropyl alcohol to remove any dirt, oil, or debris. This guarantees proper adhesion. Next, load the sealant into a caulking gun for precise application.

When applying the sealant, maintain a consistent angle and pressure. Start at one end of the joint and move steadily to the other, creating a smooth, even bead. For best results, apply the sealant in a single, continuous motion. If you need to stop, try to do so at a natural break point.

After application, use a plastic smoothing tool or your finger (wearing a disposable glove) to press the sealant into the joint and create a neat finish. This step helps to remove air bubbles and guarantee full contact with both surfaces.

Work quickly, as most silicon sealants begin to skin over within 10-15 minutes. Allow the sealant to cure fully before exposing it to water or stress.

Curing times vary, but most silicon sealants require 24-48 hours for complete curing.

Durability and Longevity

Longevity is a key factor when choosing sealants for solar panel connections. Silicon-based sealants are renowned for their durability and long-lasting performance in outdoor environments. They'll typically maintain their effectiveness for 10 to 20 years, depending on the specific product and environmental conditions.

You'll find that these sealants resist UV radiation, extreme temperatures, and moisture, making them ideal for solar panel applications. They don't crack, shrink, or become brittle over time, guaranteeing a consistent seal throughout the system's lifespan. High-quality silicone sealants also maintain their flexibility, allowing for natural expansion and contraction of materials without compromising the seal.

To maximize durability, you should choose a sealant specifically formulated for solar panel use. These products often contain additives that enhance their resistance to environmental stressors.

Regular inspection and maintenance of sealed connections will help identify any potential issues early on. If you notice any signs of degradation, it's best to reapply the sealant promptly to prevent water ingress and guarantee continued protection.

Butyl Tape in Solar Installations

Butyl tape plays an essential role in solar panel installations, serving as an effective sealant for various connections. You'll find it used to seal junction boxes, wire entry points, and gaps between panels. It's a popular choice due to its exceptional water-resistant properties and long-lasting adhesion.

When you're working with butyl tape in solar installations, keep these key points in mind:

- It's highly flexible, allowing for expansion and contraction with temperature changes

- Butyl tape adheres well to various surfaces, including metal, glass, and plastic

- It can withstand extreme temperatures, from -40°F to 200°F

- The tape is UV-resistant, guaranteeing longevity in outdoor applications

- It's easy to apply and doesn't require special tools or equipment

You'll appreciate butyl tape's ability to create a watertight seal, protecting your solar panel system from moisture intrusion.

It's also resistant to ozone and weathering, making it ideal for long-term outdoor use. When applying butyl tape, verify the surface is clean and dry for peak adhesion.

You can rely on this versatile sealant to help maintain the integrity of your solar panel connections for years to come.

Weatherproof Junction Boxes

When installing solar panels, you'll need to guarantee your junction boxes are truly weatherproof.

Consider the enclosure design and check for appropriate ingress protection (IP) ratings to guard against water and dust infiltration.

Don't forget to use high-quality sealants and gaskets made from materials like silicone or EPDM rubber to create a watertight seal around cable entry points and box covers.

Waterproof Enclosure Design

To guarantee the long-term reliability of solar panel connections, a properly designed waterproof enclosure is essential.

You'll want to ascertain your enclosure meets IP65 or higher standards, which protect against dust and water jets. Consider using high-quality materials like UV-resistant plastics or corrosion-resistant metals to withstand harsh outdoor conditions.

When designing your waterproof enclosure, focus on these key elements:

- Gasket seals: Use durable, weather-resistant gaskets to create a tight seal between the enclosure and its lid.

- Cable glands: Install waterproof cable glands to prevent moisture ingress where wires enter the enclosure.

- Drain holes: Include small drain holes at the bottom to allow any condensation to escape.

- Ventilation: Incorporate breathable membranes to prevent pressure buildup while maintaining waterproofing.

- Locking mechanisms: Use secure latches or screws to keep the enclosure tightly closed.

Don't forget to test your enclosure design thoroughly before implementation.

You can use water spray tests or submersion tests to verify its effectiveness. By carefully considering these aspects, you'll create a robust waterproof enclosure that protects your solar panel connections from the elements, ensuring peak performance and longevity.

Ingress Protection Ratings

Building on the concept of waterproof enclosures, it's important to understand Ingress Protection (IP) ratings for weatherproof junction boxes. These ratings indicate how well a junction box protects against solid objects and liquids. The IP rating consists of two digits: the first represents protection against solids, and the second against liquids.

For solar panel connections, you'll want to look for junction boxes with high IP ratings. An IP65 rating, for example, means the box is dust-tight and protected against water jets. IP67 offers even better protection, being dust-tight and able to withstand temporary immersion in water.

When selecting a junction box, consider your local climate and installation environment. In areas with heavy rainfall or high humidity, opt for boxes with higher liquid protection ratings. For dusty or sandy locations, confirm a high solid protection rating.

Remember that the IP rating applies to the entire assembly, including cable glands and connectors. Confirm all components meet the required protection level to maintain the overall integrity of your solar panel connections.

Sealant and Gasket Materials

After selecting a junction box with the appropriate IP rating, you'll need to focus on the sealant and gasket materials used to maintain its weatherproof integrity. These materials play an essential role in preventing water ingress and guaranteeing the longevity of your solar panel connections.

When choosing sealants and gaskets, consider the following options:

- Silicone-based sealants

- EPDM rubber gaskets

- Butyl rubber tapes

- Polyurethane sealants

- Neoprene gaskets

Silicone-based sealants are popular due to their flexibility, durability, and resistance to UV radiation. They're ideal for sealing gaps and joints in the junction box.

EPDM rubber gaskets offer excellent compression set resistance and weather resistance, making them suitable for creating watertight seals between the junction box and its cover.

Butyl rubber tapes provide a quick and easy solution for sealing smaller gaps and crevices. They're self-adhesive and conform well to irregular surfaces.

Polyurethane sealants offer high adhesion strength and are particularly useful for bonding different materials.

Neoprene gaskets are known for their oil resistance and ability to withstand extreme temperatures, making them suitable for harsh environments.

When applying sealants or installing gaskets, verify all surfaces are clean and dry for maximum adhesion and sealing performance.

Waterproof MC4 Connectors

Why are MC4 connectors so popular in solar panel installations? These connectors have become the industry standard due to their robust design and excellent waterproofing capabilities. MC4 connectors feature a snap-lock mechanism that guarantees a secure, waterproof connection between solar panels and other system components.

You'll find MC4 connectors easy to use and highly reliable. They're designed to withstand harsh outdoor conditions, including extreme temperatures, UV radiation, and heavy rainfall. When properly installed, MC4 connectors provide an IP67 rating, meaning they're dust-tight and can withstand temporary immersion in water.

Here's a quick overview of MC4 connector features:

| Feature | Benefit | Importance |

|---|---|---|

| Snap-lock mechanism | Secure connection | High |

| IP67 rating | Weather resistance | Critical |

| UV-resistant materials | Longevity | High |

| Polarized design | Prevents reverse polarity | vital |

| Universal compatibility | Easy integration | Moderate |

To guarantee peak performance, you should always use genuine MC4 connectors from reputable manufacturers. When installing, make sure to follow the manufacturer's guidelines for proper crimping and assembly. This will help maintain the connector's waterproof integrity and promote long-lasting, trouble-free operation of your solar panel system.

Applying Sealants Correctly

While MC4 connectors provide excellent waterproofing, you'll sometimes need additional sealants for extra protection in your solar panel installation.

When applying sealants, it's essential to follow proper techniques to guarantee maximum effectiveness. First, clean the surfaces thoroughly and confirm they're completely dry before application. Choose a high-quality, UV-resistant silicone sealant specifically designed for outdoor use and solar panel installations.

Apply the sealant in a continuous bead around the connection points, making sure to cover any gaps or potential entry points for water. Smooth the sealant with a wet finger or specialized tool to create a uniform seal. Allow the sealant to cure fully before exposing it to water or humidity.

Here are five key points to remember when applying sealants:

- Use the right type of sealant for your specific application

- Apply in temperatures between 40°F and 90°F for best results

- Don't skimp on quantity; use enough to create a proper seal

- Avoid stretching or compressing the sealant excessively

- Regularly inspect and reapply sealant as needed to maintain protection

Common Waterproofing Mistakes to Avoid

When it comes to waterproofing solar panel connections, even small mistakes can lead to considerable problems down the line. To guarantee your solar system remains protected, you'll want to avoid these common errors.

First, don't rush the application process. Applying sealants too quickly can result in gaps or thin spots that compromise the seal. Take your time and verify even coverage.

Also, avoid using incompatible materials. Some sealants may react poorly with certain surfaces or other chemicals, so always check compatibility before use.

Another mistake is neglecting proper surface preparation. Failing to clean and dry the area thoroughly can prevent the sealant from adhering correctly.

Additionally, don't underestimate the importance of temperature. Applying sealants in extreme heat or cold can affect their performance and longevity.

Overfilling or underfilling joints is another common error. Use the right amount of sealant to allow for proper expansion and contraction.

Finally, don't forget about maintenance. Regular inspections and touch-ups are vital for long-term waterproofing success.

Maintaining Waterproof Solar Connections

Vigilance is key to maintaining waterproof solar connections. Regular inspections and proactive maintenance can prevent water ingress and guarantee your solar system's longevity. You'll need to check your connections periodically, especially after extreme weather events or seasonal changes.

When inspecting your solar connections, look for:

- Signs of corrosion or oxidation

- Cracks or gaps in sealants

- Loose or damaged cables

- Deteriorating rubber gaskets

- Accumulation of debris or moisture

If you spot any issues, address them promptly. Clean connections with a soft brush and isopropyl alcohol to remove dirt and grime. Reapply sealants as needed, using UV-resistant, weatherproof products designed for solar applications.

Tighten any loose connections, but be careful not to overtighten and damage components.

Consider upgrading to newer, more durable connectors if you're experiencing frequent problems. Modern MC4 connectors offer excellent water resistance and durability.

Also, guarantee proper cable management to prevent water from traveling along wires and reaching connection points. By staying vigilant and addressing issues quickly, you'll maintain the integrity of your solar panel connections and maximize your system's efficiency and lifespan.

Testing for Water Resistance

After confirming your solar connections are properly sealed, it's important to verify their water resistance. You can perform several tests to confirm the effectiveness of your sealing methods. Start with a visual inspection, looking for any gaps or imperfections in the sealant. Next, conduct a water spray test using a hose to simulate rain conditions. Observe the connections closely for any signs of water ingress.

For more thorough testing, consider these methods:

| Test Method | Description |

|---|---|

| Submersion | Submerge sealed connections in water for a set time |

| Pressure Test | Apply pressurized water to connections |

| Thermal Cycling | Expose connections to temperature extremes |

| Humidity Chamber | Subject connections to high humidity environments |

| Salt Spray | Test resistance to corrosive saltwater exposure |

After testing, inspect the connections for any moisture penetration. If you detect water ingress, reapply sealant and test again. Remember, regular testing is vital for maintaining the integrity of your solar panel system. By routinely checking water resistance, you'll guarantee the longevity and efficiency of your solar connections, protecting your investment from water damage and potential electrical issues.

Climate Considerations for Sealant Selection

Your solar panel system's longevity and performance heavily depend on choosing the right sealant for your specific climate. When selecting a sealant, consider the following climate factors:

- Temperature fluctuations

- UV exposure

- Humidity levels

- Precipitation patterns

- Wind conditions

In hot climates, opt for sealants that can withstand high temperatures without degrading or losing elasticity. Look for products with excellent UV resistance to prevent premature breakdown from intense sunlight.

For cold regions, choose sealants that remain flexible at low temperatures to avoid cracking during freeze-thaw cycles.

In humid areas, select moisture-resistant sealants that prevent water infiltration and mold growth. Coastal regions require sealants with superior salt-spray resistance to combat corrosion.

For areas with heavy rainfall, verify your sealant has excellent water-shedding properties and strong adhesion to prevent leaks.

Wind-prone locations demand sealants with high tensile strength to resist lifting and tearing. Consider multi-purpose sealants that address multiple climate factors simultaneously.

Always check the manufacturer's specifications and temperature ranges to ascertain compatibility with your local climate conditions. By carefully matching your sealant to your climate, you'll maximize your solar panel system's protection and efficiency.

Professional Vs DIY Waterproofing Methods

When it comes to waterproofing solar panel connections, you'll need to decide between professional and DIY methods.

Professional installation typically guarantees a higher quality seal and often comes with warranties. Certified installers use industry-standard techniques and have access to specialized tools and materials. They're trained to identify potential weak points and can apply sealants with precision.

If you're considering a DIY approach, you'll need to be confident in your skills and knowledge. You can find waterproofing kits designed for solar panels, which include sealants, tapes, and application tools. However, be aware that improper application can lead to leaks and damage. It's essential to thoroughly clean and prepare surfaces before applying sealants.

Key differences between professional and DIY methods include the quality of materials used, the level of expertise in application, and the time investment required.

While DIY can be cost-effective, it may not provide the same level of protection as professional work. If you're unsure about your ability to properly seal connections, it's best to consult a professional to avoid potential damage to your solar system.

Frequently Asked Questions

How Long Do Solar Panel Sealants Typically Last Before Needing Replacement?

You'll find that high-quality solar panel sealants typically last 10-15 years before needing replacement. However, factors like climate, installation quality, and sealant type can affect longevity. It's best to inspect seals regularly for peak performance.

Can Sealants Affect the Efficiency or Performance of Solar Panels?

Yes, sealants can affect your solar panels' efficiency and performance. If you use low-quality or incorrectly applied sealants, they might block sunlight, trap heat, or cause microcracks. It's essential you choose high-quality, transparent sealants for best results.

Are There Eco-Friendly or Biodegradable Options for Solar Panel Sealants?

You'll find several eco-friendly sealant options for solar panels. Look for biodegradable silicone-based products or those made from plant-based materials. They're becoming more common as manufacturers focus on sustainability. Always check compatibility with your specific panels before applying.

How Do Sealants Interact With Different Solar Panel Materials or Coatings?

You'll find that sealants interact differently with various panel materials. They'll adhere better to some surfaces than others. It's vital to choose a compatible sealant that won't degrade your panels' coatings or affect their performance over time.

What Safety Precautions Should Be Taken When Working With Solar Panel Sealants?

When working with solar panel sealants, you'll need to wear protective gear like gloves and goggles. Guarantee proper ventilation, read safety data sheets, and avoid skin contact. Don't ingest or inhale fumes. Always follow manufacturer's safety guidelines.

In Summary

You've learned about various methods to seal solar panel connections against water intrusion. Whether you're using silicon-based sealants, butyl tape, or weatherproof junction boxes, it's essential to choose the right solution for your climate. Remember to maintain and test your waterproof connections regularly. While DIY options exist, consider professional installation for ideal protection. By ensuring your solar panel connections are properly sealed, you'll extend the life and efficiency of your system.

Leave a Reply